The concrete placing method will depend on the rate of concreting planned, type of structure, the quantity of concrete required to be poured in one go, the equipment or manpower available for placing and compacting concrete, formwork design, the time required for the initial setting of concrete, and even the…

Transportation of Concrete and Checklist for Concrete Transportation

Transportation of concrete is a significant activity in the production of concrete. The time taken in transit mixer should be a design parameter as it depends on the initial setting time of concrete as well as the requirement of workability at the placing point. The method of transportation adopted at…

Types of Concrete Vibrators

Compaction of concrete is best done by vibration. Rodding, tamping and spading are all ways of removing entrapped air from concrete and compacting it; however, the best and most effective method is vibration. The concrete mix gets fluidized on vibration, and the internal friction between the aggregate particles reduces, resulting…

What is Compaction of Concrete? Its Methods, Guidelines, and Duration

Compaction or consolidation of concrete is necessary to remove entrapped air which is present in concrete after it is mixed, transported, and placed. Compacting also helps eliminate stone pockets and thereby eliminates all types of voids that may possibly be left in the concrete, causing a reduction in strength as…

What is Concrete Cover? Concrete Cover Specifications for Reinforcement in Different Codes

Cover to reinforced concrete is the minimum thickness of concrete provided over the reinforcement steel, measured from the exposed concrete surface to the closest reinforced steel surface. Concrete is needed to cover and protect steel reinforcement within its body. The concrete cover is often subjected to impact, wear, and access…

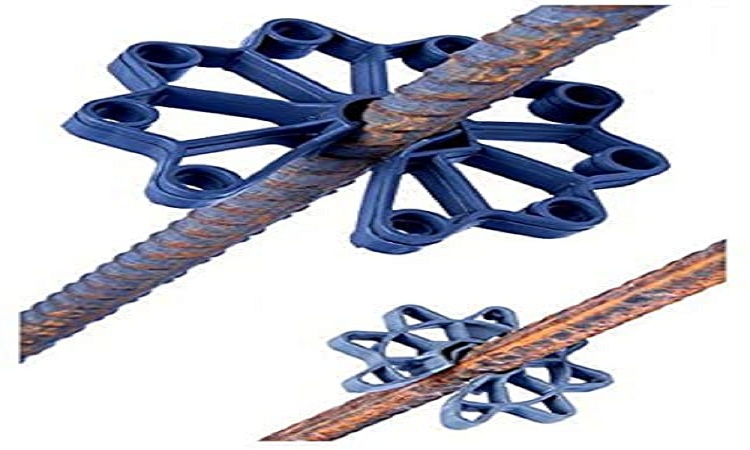

Different Types of Cover Block/Spacers at Construction Site

Cover blocks or spacers are divided based on the materials utilized in their manufacturing process. These are given below for various spacers: Metal Spacers Plastic Spacers Concrete Block Spacers Wood Spacers Metal Spacers Metal spacers are commonly used and are interchangeable with slab bar supports. They provide good anchorage or…

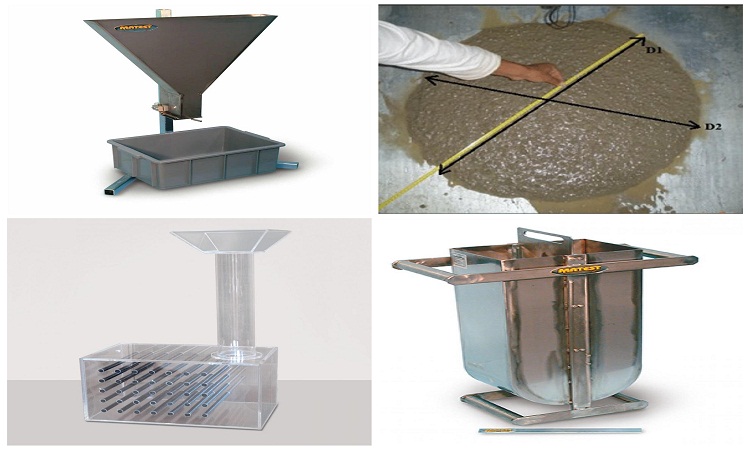

Methods of Testing Self Compacting Concrete Workability

There are three basic properties of self-compacting concrete (SCC) namely flowability, passing ability (free from blocking due to presence of reinforcement), and resistance to segregation (stability/homogeneity). Therefore, it is very essential to carry out field trials or mock trials to assess these attributes. Unfortunately, so far not a single test…

What is Plastic Cracking of Concrete? Its Occurrence, Causes, and Preventive Measures

Plastic cracking of concrete occurs when the concrete has just laid and finished is exposed to warm drying wind, and then develops cracking over the surface of the fresh concrete. The main causes of cracking can be attributable to the following. Poor workmanship and negligence. Defects and errors in construction…

What Causes Cracks in Concrete Basement Floors?

Cracks in the concrete basement floor can be a reason for panic for homeowners. Most concrete basement floor cracks are normal and do not need to be repaired. However, some cracks in the concrete basement floor can let in water, moisture, and dangerous soil gasses. Is It Normal For Concrete…

Types of Concrete Mixers

What is Concrete Mixer? Concrete mixers are machines that mix cement, aggregates, and water together to produce the concrete mechanically. A good concrete mixture shouldn’t only uniformly mix the concrete ingredients, but should also discharge the concrete mix without disturbing it’s uniformly. This can be judge by the uniform consistency…