Pumped concrete moves as a cylinder riding on a thin lubricating film of grout/mortar on the internal diameter of the pipeline. Before pumping begins, the entire pipeline’s interior diameter must be coated with either grout or a specialized commercial primer using the methods for 100% coating of the pipe walls…

What is Pumped Concrete? Advantages and Disadvantages of Pumped Concrete

Pumped concrete is the concrete that is transported to heights by means of pumping using concrete pumps. Pumped concrete is utilized where a large quantity of concrete work is involved at a greater height, where different methods of transport are not easy to do. Concrete pumps have been known for…

Mineral Admixtures – Its Types, Advantages and Their Effects on Concrete

Mineral admixtures are mostly derived from other substances and not chemically manufactured. Mineral admixtures make concrete mixtures more cohesive, economical, reduce permeability, increase strength, and influence other properties of concrete. Mineral admixture impacts the nature of the hardened concrete through hydraulic activity or pozzolanic activity. Pozzolanas are cementitious materials and…

What is Durability of Concrete? Factor Affecting Durability of Concrete

The durability of concrete is defined by its capability or the ability to resist weathering action, chemical attack, abrasion, or any other deterioration process and retain its original form, quality & serviceability when exposed to its environment. Different concretes require different degrees of durability on the exposure environment and properties…

Placement of Concrete – Recommendations for Concrete Placement

The concrete placing method will depend on the rate of concreting planned, type of structure, the quantity of concrete required to be poured in one go, the equipment or manpower available for placing and compacting concrete, formwork design, the time required for the initial setting of concrete, and even the…

Transportation of Concrete and Checklist for Concrete Transportation

Transportation of concrete is a significant activity in the production of concrete. The time taken in transit mixer should be a design parameter as it depends on the initial setting time of concrete as well as the requirement of workability at the placing point. The method of transportation adopted at…

Types of Concrete Vibrators

Compaction of concrete is best done by vibration. Rodding, tamping and spading are all ways of removing entrapped air from concrete and compacting it; however, the best and most effective method is vibration. The concrete mix gets fluidized on vibration, and the internal friction between the aggregate particles reduces, resulting…

What is Compaction of Concrete? Its Methods, Guidelines, and Duration

Compaction or consolidation of concrete is necessary to remove entrapped air which is present in concrete after it is mixed, transported, and placed. Compacting also helps eliminate stone pockets and thereby eliminates all types of voids that may possibly be left in the concrete, causing a reduction in strength as…

What is Concrete Cover? Concrete Cover Specifications for Reinforcement in Different Codes

Cover to reinforced concrete is the minimum thickness of concrete provided over the reinforcement steel, measured from the exposed concrete surface to the closest reinforced steel surface. Concrete is needed to cover and protect steel reinforcement within its body. The concrete cover is often subjected to impact, wear, and access…

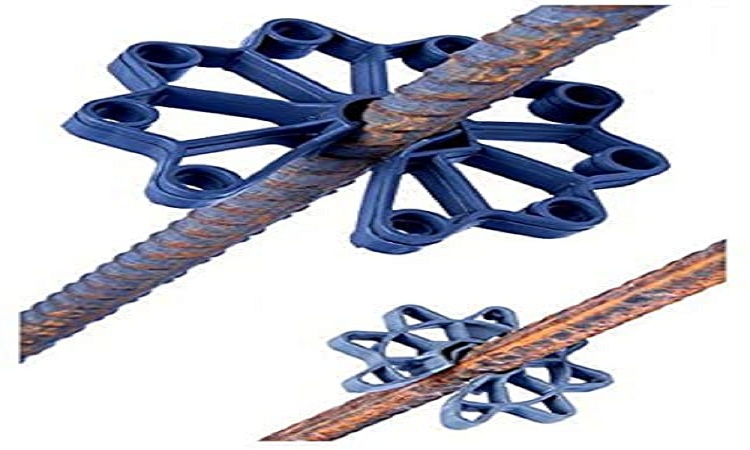

Different Types of Cover Block/Spacers at Construction Site

Cover blocks or spacers are divided based on the materials utilized in their manufacturing process. These are given below for various spacers: Metal Spacers Plastic Spacers Concrete Block Spacers Wood Spacers Metal Spacers Metal spacers are commonly used and are interchangeable with slab bar supports. They provide good anchorage or…