The chemical action between cement and water, which results in the setting and hardening of concrete, is dependent on the presence of water. Although there is normally a sufficient quantity of water for full hydration when the concrete or mortar mix is prepared, it is important to ensure that the water is either replenished/retained to enable the chemical action to be continued till such time the required strength is gained.

A significant loss of water due to evaporation from the concrete surface may result in slowing down or stopping the hydration process and resulting in the consequent reduction of strength and durability. In order to help the hydration process to continue, water in the capillaries should be prevented from evaporating. It is therefore essential to maintain an environment of high humidity around the freshly placed concrete till it attains reasonably good strength. This process is called curing of concrete.

Curing is the last step required to be taken in the process of concrete construction. This last step plays a very significant role in the concrete performance and needs the full attention of the persons involved in construction.

Concrete in its early life needs to be carefully looked after like parents looking after their newborn baby. If concrete is not nurtured properly by carrying out the required curing or protected against wind and extreme ambient conditions then the structure will lose its strength, durability, and performance will be far below the required level.

Since hydration of cement is more rapid in the first few days after fresh concrete is placed, it is important for enough water to be retained within the concrete mass during this period. This can be achieved by either reducing the evaporation losses or by replenishing the water continuously on the concrete surfaces for an adequate period of time.

Curing has a strong influence on various concrete properties and therefore it should not be taken lightly. Strength, durability, water tightness, volume stability, wear resistance, chemical attacks, and resistance to freeze-thaw cycle is much superior to a well-cured concrete than that of a concrete wherein curing was neglected, all other parameters being identical.

Besides this advantage, curing reduces shrinkage, gives better resistance to wear and impact & improves long term appearance. This is due to the fact that sufficient curing gives to the thin exposed surface a case hardened property which otherwise would not be obtained if curing is neglected. In every manner, a well-cured concrete or mortar is a better concrete or mortar.

There are two general ways by which concrete can be kept humid and moist or kept at a favorable temperature.

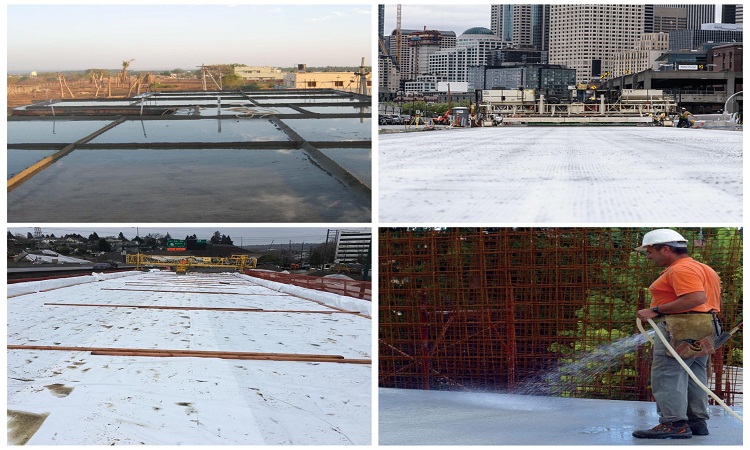

- By preserving the presence of mixing water in the concrete during the early hardening period of the concrete. Methods for curing mainly deployed are Ponding, immersion, sprinkling or fogging, spraying, wet covering using gunny bags or hessian cloth, etc.

- By prohibiting the loss of mixing water from the concrete by sealing the exposed concrete surfaces. The exposed concrete surfaces can be generally covered by a membrane formed by curing compound, plastic sheets, and impervious paper or even by leaving formwork in place.

However, at times, there is a need to accelerate curing or there is intent to handle or put to use the concrete structure earlier. This is achieved by using live steam, electrically heated forms, heating coils, pads.

The combinations of curing methods are generally selected depending on some of the following factors:

- Specifications

- Availability of curing materials

- Economics

- Types of the concrete structure (precast/cast-in-situ)

- Shape and size of the concrete surface

- Aesthetic appearance

Methods of Curing

Methods of curing of concrete given below:

- Water curing

- Membrane curing

- Steam curing

- Miscellaneous methods

Water curing

The water curing method is the best method as it satisfies all the requirements of curing, namely, promotion of hydration, elimination of shrinkage, and absorption of the heat of hydration. Water curing can be done in the below following ways:

Immersion in Water

The best concrete curing method is the total immersion of concrete in water. This method of total immersion is practically not possible unless the concrete is a laboratory test specimen or a small precast member which can be easily handled & placed in the curing pond.

Ponding

However, curing of flat surfaces such as those pavements, concrete roads, sidewalks, floors slabs can be best cured by Ponding water on the exposed top surface.

However, following precautions are necessary:

- Ponding water lost due to evaporation should be continuously filled up again.

- Ponding water should also cover the edges and corners and should be able to cover the entire surface uniformly to avoid dry spots wherein curing would be deficient.

- Water used for curing of concrete should have identical properties as that of water used for the manufacture of concrete.

- Water and the materials used for Ponding should be free of substances that will stain or discolor the concrete surfaces.

- The difference in the curing water temperature and the concrete temperature should not be more than 11oC to prevent thermal stresses that could result in cracking.

- Sufficient water should be available at the site throughout the curing period.

- Bunds of cement mortar or impervious earth to retain water should be maintained throughout the curing period.

- The height of the bunds and area of the concrete surface to be ponded must be so selected that there is at least about 25mm of water ponded on the highest surface.

Spraying Water

This method can be applied to both horizontal and vertical concrete/mortar surface. However, sufficient water is necessary throughout the curing period and round the clock.

Sprinkling with water is an excellent method when the ambient temperature is well above freezing & the humidity is low. Fogging is applied to reduce plastic shrinkage cracking until finishing operations are complete. A vertical retaining wall or concrete columns or plaster surface etc. are cured by spraying water.

Wet Covering

The exposed concrete surface is prevented from drying out by covering it with hessian, empty cement, or canvas bags. These are periodically wetted. The interval of wetting will depend upon the evaporation rate of water.

Membrane Curing

The process of applying a membrane-forming compound surface on the concrete is termed as membrane curing. The membrane serves as a physical barrier to prevent moisture loss from concrete.

Membrane curing usually used if there is an acute shortage of water or the concrete’s placed at an inaccessible site.

The various membrane forming compound are;

- Bituminous compound

- Polyester film

- Waterproof paper

- Rubber latex emulsion

- Emulsion of waxes & resins

- Emulsion of paraffin

- Plastic sheet

Steam Curing

Steam curing is used for precast concrete members. The members are heated up by steam either at low pressure or high pressure. Live steam, electrically heated pads or forms, heating coils, are used for steam curing.

Miscellaneous Methods

Infrared Radiation

This curing method is adopted in very cold climate region.

Electrical curing

The electrical curing can be done by passing an alternating current through the concrete itself between two electrodes either applied to the concrete surface or buried in.