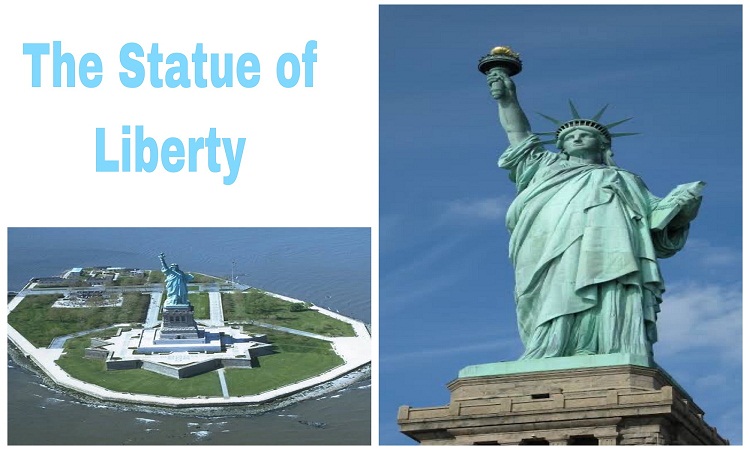

The Statue of Liberty situated in New York harbor in the U.S.A welcoming immigrants to the country is one of the marvels of the world. This wonderful Statue is a beautiful work of art and, at the same time, an excellent piece of engineering.

The enormous size and the severe design conditions called for innovation in engineering. There was another all-prevailing factor. The Statue was to be made in Paris but to be installed in the New York harbor. The Statue had to be transported over some 3000 miles (4800 Km), across the Atlantic Ocean.

The design, the making, the transportation, and the re-assembly are all engineering feats.

Why was the Statue of Liberty huge in the first place? About that a little later, but first, get the perception of the size and the work. Look at the details below. They tell us of the tremendous efforts and ingenuity in engineering and in making the Statue.

Engineering Details

- Height from base to the top of the torch: 151’1”(46.50 m)

- Foundation of the pedestal to torch: 305’1’’ (93 m)

- Length of hand: 16’5’’ (5.00 m)

- Index finger: 8’0’’ (2.44 m)

- Size of fingernail: 13’’ x 10’’ (33×25.4 cm)

- Wind speed at which Statue sways 3 inches (7.62 cm): 50 mph (80 Km/h)

- Torch sway in 50 mph (80 Km/h) wind: 5 inches (12.7 cm)

- Weight of copper used in Statue of Liberty: 200,000 pounds (90 tonnes)

- Weight of steel used in Statue of Liberty: 250,000 pounds (114 tonnes)

- Total weight of Statue of Liberty: 450,000 pounds (204 tonnes)

- Weight of concrete in the foundation: 24,000 tonnes (22,000 tonnes), the largest single mass ever poured till then

- Foundation height: 52’ 10’’ (16 m)

- Foundation measurement: Bottom – 91 Sq.ft; Top – 65 Sq.ft

- Height of pedestal: 89’ (27 m) above the foundation

- The thickness of copper sheeting: 3/32 inch (2.37 mm)

- Approximate fabric in the dress: 4,000 sq.yds (3340 sq.m)

The Engineers and the Artists

Who were the genii of engineering and art to make this wonder?

- The Statue was conceived and sculpted by August Bartholdi

- The Structural Engineer was Alexander-Gustave Eiffel who was already known for his brilliant iron railroad bridges at the time and who later designed the famous Eiffel Tower of Paris. Alexander-Gustave Eiffel designed the intricate skeleton for the Statue.

- The Architect of the pedestal was: Richard M. Hunt

- The Chief Project Engineer was: General Charles P. Stone. General Charles was in charge of the construction project including the foundation, the pedestal, and the reassembly of The Statue of Liberty.

Method of Fabrication

The material of construction was an important consideration. Stone and bronze were discounted because of their weight. Besides, the use of stone and bronze would mean higher expenses.

The Statue was fabricated using copper sheets. The thickness of the sheet was 2.37 mm. the method of fabrication was what is called the “Repousse Process”.

The “Repousse Process” is a technique for creating sculpture forms. The system of working is to hammer a sheet metal inside moulds. The “Repousse Process” would make an object lighter than the cast metal. The “Repousse Process” was the only system of working available then that would allow such a “monumental” work to be shipped overseas.

How did it all start in the first place?

In 1865, in Paris, several French intellectuals had gathered at a small dinner party. These intellectuals were opposed to the oppressive regime of Napoleon III. One of the intellectuals, Laboulaye, was the host. Laboulaye was a scholar, a jurist & the leader of the “Liberals”. At that party was another bright man: Frederic-Auguste Bartholdi. Bartholdi was only 31 at that time but was a successful sculptor already. The “Liberals” were the political group that dedicated themselves to the establishment of a French republican government. This government would be modeled on America’s constitution.

The intellectuals were discussing and admiring America’s success in establishing a democratic government and abolishing slavery at the end of the Civil War.

The talk turned to the historic ties and love of liberty France and America shared. Laboulaye noted that there was “a genuine flow of sympathy” between both countries. He called France and America “the two sisters.”

As Laboulaye continued speaking and reflected on the centenarian of American independence in 1876, only 11 years in the future, he commented: “Wouldn’t it be wonderful if people of France gave America a great monument as a lasting memorial to the independence and thereby showed that the French government was also dedicated to the idea of human liberty?”

The question of Laboulaye was casual, but it struck a responsive chord in Bartholdi. After many years Bartholdi wrote: “Laboulaye’s idea interested me so deeply that it remained fixed in my memory.”

So was sown the seed of inspiration that would turn into an all-time, world-class beautiful monument in art and engineering, called the STATUE OF LIBERTY.

Why the Statue was conceived so huge?

The Statue was conceived and designed by the great sculptor of his time, Bartholdi. Bartholdi lived in his time. He liked the art on a grand scale. He was not alone in this passion for art on a grand scale. During the 19th century, large-scale public monuments were a popular art form. It was an age of display inspired by classical Greek and Roman civilizations. Most memorials reflected either the dress or architecture of those ancient times.

The great sculptor and his mysterious inspiration?

The life and work of the great sculptor is interesting and inspiring.

Bartholdi was born on 2nd August 1834 in a well-to-do middle-class family in Colmar, France. Bartholdi’s father was a civil servant and a prosperous landowner. The father died when Bartholdi was only two years old. So Bartholdi’s stern and possessive mother Charlotte raised the child.

Many people that mother Charlotte Bartholdi (1801 – 1891) was the model for the Statue. Others think that the Statue was based on Bartholdi’s early drawings for a never-commissioned Statue in Egypt. The sculptor’s true inspiration for his work of art remains a mystery.

The expeditor?

Bartholdi drew up plans for the Statue of Liberty in 1867. The Statue of Liberty was to be in the form of a robed female Egyptian peasant, with light beaming out from two places: (1) a headband and (2) a torch held dramatically upward into the skies. But the project was never commissioned.

In 1870, with the beginning of the Franco-Prussian war, Bartholdi became a major in the French army. He was stationed in his home city of Colmar. When the Germans annexed that region and made the resident’s German citizens, the reality of the word “liberty” took significance to Bartholdi and the word took a new, personal meaning for him.

The Site for installation

Engineering was one important aspect of the making of the Statue. Another important aspect was the location of the monument. Where the Statue would be installed?

On June 8, 1871, Bartholdi sailed aboard the ship Pereiere, from Le Havre, France, for New York. He carried letters of introduction from Laboulaye to some of America’s most influential men. Bartholdi was on a mission to select the installation site.

Bartholdi found the perfect spot for the Statue even before he landed on America’s shores. The spot was the Bedloe’s Island in the Harbor of New York. He later wrote about the location site of the Statue:

New York was the perfect locale since it was Where people get their first view of the New World. I’ve found an admirable spot. It is Bedloe’s Island, in the middle of the bay.

The Island was renamed “Liberty Island” in 1956.

The time Schedule and Finance

The Third Republic of France was established in 1874. With the change in times, Laboulaye and Bartholdi agreed that time had come for the work on the Statue. The next step was finance.

Bartholdi and Laboule agreed that the Statue would be prohibitively expensive to produce. They decided that the cost should be shared between France and America both countries. France would pay for the Statue. America will pay for its pedestal and foundation. A fund-raising committee called the “Franco – American Union” was formed, with members from both nations France and America. Elaborate fundraising events were staged.

Enough was collected to begin the work on the Statue, but the goal of completing it in time for America’s 100th independence anniversary (July 4, 1876) was impossible.

At the end of the extraordinary efforts, the following dates were achieved.

- Construction began in France: 1875

- Statue completed in France: June 1884

- Statue final assembly on the pedestal in America; 1886 (110th independence anniversary of America)

The design of the Statue of Liberty

The construction of the statue began in 1875. Bartholdi has chosen Caget, Gauthier, and Company as his workshop. Its craftsmen were experts in the art of Repousse.

Bartholdi decided to use thin sheets of copper, light, and relatively flexible metal instead of casting the copper, beating the metal into shape over sculpted wooden moulds. This copper outer skin will “hang” on an inner, tower-like framework of iron.

The copper plates or sections for the giant hand and tablet were the copper sculpture. Temporary braces were put to prevent the plates from buckling and holes were then punched for the rivets which connected all the plates into one great figure.

Bartholdi designed and built a 36 ft (11 m) high plaster model. The Statue had to be strong enough to withstand the aggressive weather conditions and yet light enough to be shipped to America.

The solution was to make the Statue of Liberty hollow, with the outer shell support on an inner iron framework.

The construction of Statue of Liberty

Bartholdi cut his master model into sections and made thousands of meticulous measurements before scaling up each section into a full-size plaster replica. Wooden moulds were then carved to exact match, each enlarged section. The finished “skin” was made through the hammering of Three Hundred thin copper sheets into the moulds.

Meantime, the Structural Engineer Alexander Gustave Eiffel was working on the interior framework, which was to be the tallest iron support structure attempted up to that time. He came up with a tremendous design.

The outer shell of the Statue is non-load-bearing and floats on its frame. A structure of iron ribs radiates horizontally from a central backbone of four vertical girders that reach from the base to the nape of the neck. Attached to this the armature, made of spring-like iron bars. The bars curve and twist to follow the shape of the Statue, like the structure of a dressmaker’s dummy. To reduce the direct and potentially corrosive contact of copper and iron, the sections of copper skin are hung on this interior skeleton. The skeleton has copper brackets covered with an insulating material to keep the two metals apart.

The 1st rivet was driven into the Statue, on October 24, 1881, by the American ambassador to France, Levi P. Morton. “The Statue of Liberty commences to reach above the houses, and by next spring will see it overlook the entire city.” Bartholdi wrote to his American compatriots: By December.

In June 1884, the statue received the final touches and French Prime Minister Jules Ferry and Ambassador Morton dedicated the Statue with much pomp. However, when Bartholdi invited the celebrating party to climb with him some 171 (One Hundred Seventy-One) steps up the Statue of Liberty, few accepted this challenge.

In America

The Statue was stored and exhibited in France till the spring o 1885. Then the Statue was dismantled in 350 individual, meticulously numbered places for the voyage to America, in 214 enormous wooden crates. The Statue was shipped outland a transport ship of the French frigate called “Isere”.

the Statue arrived at Bedloe’s Island on June 15, 1885. The Statue began to rise in May 1886. It took six months to mount the statue to the base. The final assembly of the Statue & the pedestal was achieved in 1886.

The completion of Statue of Liberty

The Statue was declared open and thus the project was completed on October 28, 1886. Bartholdi pulled the cord and revealing the Statue’s gleaming copper face to the world. A masterpiece of engineering was now completed.

Maintenance and Repairs of Statue of Liberty

From 1886 to 1902, the Statue was maintained by the Lighthouse Board, an agency of the federal government, in the annexation with the Army and the American Committee. In 1901, the War Department assumed responsibility, making some much-needed repairs, patch up, and improvements to the Statue and the Island.

Here are few Interesting things you may not have known about the Statue of Liberty:

- Its full name is Liberty Enlightening the World.

- It was a bounty from France, given to America in 1886.

- The head of the statue was displayed at the World’s Fair in Parish in 1878.

- She holds a torch and tablet upon which is inscribed the date of the American Declaration of Independence.

- From the ground to the top of the torch the Statue measures 96 meters and weighs 204 metric tonnes.

- Lady Liberty wears a size 879 shoe.

- Visitors have to climb 354 stairs to reach the Statue of Liberty’s crown.

- There are 25 windows in the crown.

- Approximately 4.5 million people visited the Statue in 2019. By way of comparison, around 7 million people visit the Eiffel Tower each year, and 3.75 million visits the London Eye.

- The Statue of Liberty has an iron infrastructure and copper exterior which has turned green due to oxidation. Although it’s a sign of damage, the patina also acts as a form of protection from further deterioration.

- Edouard de Laboulaye provided the idea for the Statue of Liberty, while Frederic-Auguste Bartholdi designed it.

- Laboulaye proposed that a great monument should be given as a gift from France to the United States as a celebration o both the union’s victory in the American Revolution and the abolition of slavery.

- Three Hundred different types of hammers were used to create the copper structure.

- The Statue of Liberty’s face was said to be modeled on the sculptor’s mother, Charlotte.

- The Statue of Liberty’s original torch was replaced in 1984 by a new copper torch covered in 24k gold leaf.

- Despite the positive meaning of the Statue of Liberty American independence and the abolition of slavery – African Americans saw the Statue as an iconic image of America.

- The Statue of Liberty became the emblem of immigration during the second half of the 19th century, as over 9m immigrants came to the United States, with the Statue often being the first thing they saw when arriving by boat.

- The Statue’s well-known cinematic appearance was in the 1968 film planet of the Apes, where it is seen half-buried in the sand.

- It is also destroyed in the movie’s independence day and the day after tomorrow.

- The cost of the Statue of Liberty was funded by contributions from both the French and the Americans. In 1885, a New York newspaper entitled “World” announced that $102,000 had been raised from donors and that 80% of this total amount had been received in sums of less than one dollar.

- Groups in Boston and Philadelphia offered to pay the full cost of the construction of the Statue of Liberty, in return for its relocation.

- When the Statue of Liberty was first erected in 1886 it was the tallest iron structure ever built.

- In 1984 the Statue of Liberty was listed as a UNESCO World Heritage Site.

- In high winds of 50mph or more, Lady Liberty can sway by up to 3 inches while her torch can move 5 inches.

- Lady Liberty is thought to have been hit by around Six Hundred bolts of lightning every year since she was built. A photographer captured this for the first time in 2010.

- Two people have committed suicide by jumping off the Statue, one in 1929 and the other in 1932, while many others have jumped and survived.

- American poet Emma Lazarus wrote a poem about the Statue of Liberty in a sonnet called “The New Colossus”. In 1903 the poem was carved on a bronze plaque and placed inside the lower level of the pedestal on the Statue.

- The Island in which the Statue of Liberty stands was previously called Bedloe Island, but its name was changed in 1956 to Liberty Island.

- There are various replicas of the Statue of Liberty, including a smaller version in Paris, and one on the Las Vegas Strip in Nevada.

- In 1944 the lights in the crown of the Statue of Liberty flashed “dot-dot-dot-dash” which in the Morse code means V, for Victory in Europe.

- Andy Warhol painted “Statue of Liberty” as part of his Pop Art series in the 1960s and it is estimated to be worth in excess of $35m.

- The Statue functioned as a lighthouse for 16 years, lighting a distance of up to 24 miles away.

- The Statue will be celebrating its 135th birthday in October 2020.

- Miss America, the comic book character, was granted her power by the Statue.

- After the terrorist attacks of September 11th, 2001, the Statue was closed for security reasons, with the pedestal reopening in 2004, and the Statue in 2009, but only a limited number of visitors are able to go up to the crown.

- The Statue was again closed in 2012 due to the effect of Hurricane Sandy.

- The Statue sustained minor damage in 1916 when the German saboteur set off an explosion during World War One. The torch-bearing arm suffered the most damage, with refitment works costing $100,000. The stairs in the torch of the Statue of Liberty were then closed to the public for safety reasons, and have remained closed ever since.

- Private boats are not allowed to dock at Liberty Island and Ellis Islands.

- The Statue of Liberty’s 300 copper pieces were transported to America in 214 crates on the French ship Isere, which almost sank in stormy seas.

- Two images of the Statue appear in a $10 bill.

- The cost of building the statue and pedestal amounted to over $500,000, over $10m in today’s money.

The Inspection Report of Statue of Liberty

In the early 1980s, the Statue was given a thorough examination and it was found to be disintegrating. Over a century of high-level exposure to the natural elements and condensation from the breath of millions of visitors climbing up the inside had caused severe corrosion.

In the latter year, some of the rivets that had held the copper skin together had given way, allowing more moisture to seep into the vulnerable iron structure and leakage of water was observed through these gaps. The iron armature connecting the copper plates to the framework was severely corroded. The whole network, including the rivets, had to be renewed with modern materials.

Nearly 1800 bars had to be completely replaced. The torch was in danger of falling off and the torch-bearing shoulder needed reinforcing.

The restoration project and the scaffolding

The Statue was encased in what was probably the largest freestanding scaffolding structure ever and statistics were fed into a computer to create detailed new structure plans. French craftsmen rebuilt the torch, replicating Bartholdi’s original design using the Repousse technique and master gliders from Paris gold-leafed the flame with 24-carat gold so that it gold gleam when floodlit.

Over the years the copper had lost its original color and acquired a naturally weathered, pale-green patina. When the Statue of Liberty was cleaned, this patina had to be carefully preserved as it formed a protective coating against corrosion. On the inner surface, seven layers of old paint that were trapping moisture in the seams had to be frozen and cracked off with sprays of liquid nitrogen cooled to (-) 163o C. the layers of tar beneath them were blasted off with jets of sodium bicarbonate solution.

The restoration engineering and two technologies

Replicas of each of the rusted bars, required to be replaced, from the armature were made in stainless steel. Stainless steel does not react corrosively with copper as iron does. This job had to be done section by section. One inherent limitation had to be observed. An engineering situation gave this limitation. More than 12 bars could not be removed for any 24 hour period. If more than 12 bars were removed, the Statue’s stability would be jeopardized.

To prevent contact between stainless steel and copper, protective waxy layers of Teflon tape were placed between the bars and the skin. To guard against the build-up of condensation inside, the renovated stairwell was given wider railings, and a glass-enclosed hydraulic elevator was installed. For those who cannot make the whole climb, closed-circuit televisions relay images of the Statue’s interior, showing how the Statue has been constructed and improved.

Another engineering feat was a remarkable achievement of the combination of two technologies a century apart. In 1985 a new copper flame was made, glided with thin but durable sheets of gold leaf. This leafing is rain-resistance and has a warm, rich, golden glow.