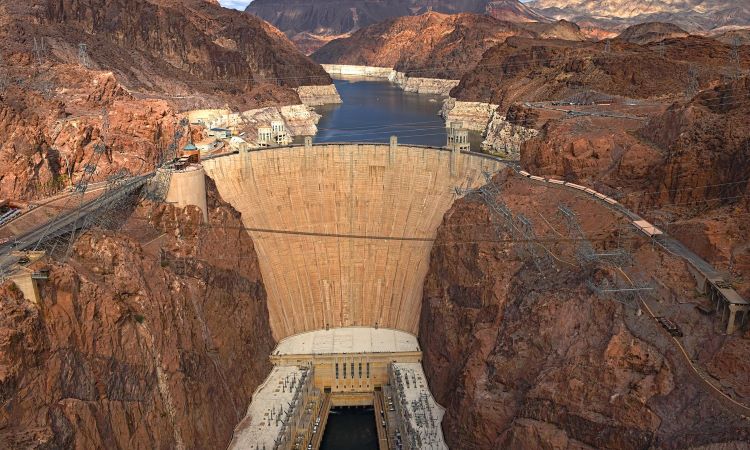

The Hoover Dam, standing 726 feet over the bedrock of the Colorado River, between the states of Nevada & Arizona, United States of America, is considered one of the best technological wonders of the globe. Before Hoover was built, the lands along the Colorado River were subject to annual flooding & intermittent droughts. Now the threat of floods has been reduced and a year-round reliable supply of water for the seven states (Arizona, California, Colorado, Nevada, New Mexico, Utah & Wyoming). Nowadays, the Colorado River supplies over 20 million people with drinking water and irrigates over 1.5 million agricultural acres which would otherwise be unusable and barren.

The construction of the dam was started in 1931, with the last concrete poured in 1935. In spite of the remote location of the Dam & difficult working conditions, Six Companies, etc. known as the ‘Big Six’ means Six large American contractors namely Utah Construction, Pacific Bridge, H. W. A. Bechtel, MacDonald & Kahn, Morrison-Knudsen, and H. J. Sea merged to form this large company, still completed the project two years ahead and well within the budget.

In 1985, Hoover Dam was considered a National Historic Landmark. In 1955, the American Society of Civil Engineers named Hoover Dam as one of the Seven Modern Civil Engineering Wonders of the United States. And in 1999. Hoover Dam was selected as one of the Top Ten Construction Achievements of the 20th Century through a poll authorized by the organizers of the construction, aggregates, and ready mixed concrete industries trade show.

Hoover’s Legacy

Hoover Dam is named after Herbert Hoover, the 31st President of the United States. The idea to build Hoover Dam was formally proposed in a 1922 report prepared under the Kinkaid Act and submitted to Congress on February 28. However, the Bureau of Reclamation opened bids for the construction of the dam in 1931. President Hoover strongly supported the construction of the high-rise concrete dam. He also advocated that the project should be self-supporting and financed through the sale of the hydroelectric power generated at the dam. To this day the operation and maintenance of the facility continue to be solely supported by the revenues from power sales.

Necessity

Before the Hoover Dam was constructed, the Colorado river flowed uninterrupted along its 1,450 miles course from the Rocky Mountains to the Gulf of California. For 12 million years the Colorado river relentlessly carved out the Grand Canyon, Marble Canyon, and other places along its path. As it cut its way through deserts. canyons and mountainous plateaus, Colorado carried with it tons of silt to the lower Colorado and eventually the Gulf of California. Spanish settlers noted the reddish color of its silt and they gave it the name we know it by, the Colorado river.

Every spring the Colorado river flooded low-lying areas along its route. The quantity of water could be great as the Colorado basin drains an area of over 242,000 square miles. The silt that it carried created a huge delta in the Gulf of California. In the recent hot southwestern summers, the flow of the Colorado river reduced to a trickle. For many years this was the natural cycle of the river.

In the 19th century, when the area along the lower Colorado began to be settled the inconsistent nature of the river made it an unreliable source for irrigation. The wanton destruction caused when the river flooded in the spring had a deep impact on the farmlands near its banks. In reality, the damage caused so much attention that by the 1920s, it had become necessary and politically expedient to try to control the damage caused by flooding along the path of the lower Colorado.

Some Interesting Facts About the Hoover Dam

- It is…

- 726.4 feet high (221.5m)

- 1,244 feet across at the top (379.3m)

- 660 feet thick at the base (201.2m)

- 45 feet thick at the top (13.7m)

- It…

- weighs 6.6 million Ton

- which can stock up to 2 years ‘average’ flow from the Colorado River.

- maximum depth of Lake Mead built by the dam is 590 feet (179.9m)

- the length of Lake Mead is 115 miles (185km)

- has a power generating capacity of 2.9 M kilowatts

- which cost the US $49 million to build Hoover Dam

- the US $165 million to complete the Boulder Canyon Project which consists of the Imperial Dam, Hoover Dam & the American Canal

- dam contains about 4,360,000 cu.yards (33,33,656 CuM) of concrete

- there are 96 million lbs. (43637 MT) of steel and metalwork used by the dam, but none of it is within the dam

- approx. 16.000 men and women worked on the project

- about 3,500 people were employed at any specific time

- death toll during construction was 96

- Construction on the Hoover Dam started on Sept. 30, 1930. The last concrete was filled in 1935.

- This structure was the first and single structure to consist of more volume of masonry than the Great Pyramid at Giza.

- The concrete utilized to make Hoover Dam was cooled with the cold water running through the inserted tubes that speed up the heat dissipation process which would otherwise have taken more than a century to cold down.

- Once the Hoover dam ranked as the world’s highest, it now ranks as 18th highest. Hoover Dam may store up to 9.2 trillion gallons of the water of the Colorado River in its reservoir, Lake Mead.

- Hoover Dam has seventeen generators giving it the capacity to make over 2,000 MW of electricity.

- Hoover Dam is part of a system that provides water to over 18 million people in the southwest United States.

Design

The structural design was initially created by Bureau of Reclamation engineers, but architect Gordon B. Kaufman & Native American artist Allen True helped create the structure’s look to make the dam an Art Deco masterpiece. Kaufman simplified & modernized the different parts of the dam.

The Hoover Dam was designed as an arch-gravity type, which implies two systems were employed. The arch system performs as a segment of a ring wedged between the walls of the canyon. The system of gravity is a little more complex as it deters the dam from sliding & also from an overturning movement. Compromising the shape of the dam under load to meet the deflection & other conditions was “tricky” & presenting the engineers with an extremely complex and lengthy investigation. In those days, there were no computers – only the slide rule and log tables were used extensively for calculations. The Hoover Dam’s criteria & calculations, adopted in the late 1920s, have validated the Bureau’s engineers as reaching the top of their profession.

Construction

The construction of the dam started in March 1931. Major six companies including government bodies were appointed to accomplish this mega undertaking project. The site was remote and the initial task was to build road infrastructure for access to materials, machines, and people.

High Scalers

The 1st job work at the site was to remove the loose boulders by blasting them utilizing the dynamite at the edge of the canyon that was at 300 to 400 feet (90 to 120 m) height. It was hard & dangerous work, perhaps the most physically demanding work on the whole project. Weighted with tools & water bags, the men would descend the canyon walls. Dropping themselves with ropes & making holes with jackhammers and putting dynamite into it was the most challenging task. Workers and people responsible for this project were from the circus, acrobats, sailors & native American Indians.

Diverting the River

Colorado River flows between 700 ft (213m) high canyon walls on both sides. Prior to the concrete arch-gravity type dam construction could begin the river required to be diverted through the diversion tunnels. This diversion allows the water to bypass the dam foundation site & later on be used for the electric plant generators.

To reroute the river’s flow around the project site, four tunnels were drilled through the canyon walls, two on the Nevada side and two on the Arizona side. The diameter of these tunnels was 56’ each. To speed up the work of drilling the holes, a “drilling jumbo” was built on the back of an old ten-ton truck. The jumbo was backed up to the working face & from 24-30 drills went to work, drilling powder holes into the rock. This jumbo allowed half of the tunnel face to be worked on and all the holes were drilled at once. When the drilling of holes was completed, the jumbo moved to the other side of the face & began drilling the other side of the face, while the completed holes were packed with powder & wired. When both the sides were drilled, the jumbo was removed. A total of eight such jumbos were constructed. The holes were poured with dynamite & the rock was broken up by the explosions. A ton of dynamite was utilized for every 14 feet (4.25m) of the tunnel dug.

In March of 1932, work started on lining the tunnels with concrete. The concrete lining was 3 feet (0.91 m) thick. It reduced the finished tunnel diameter to 50 ft. (15.25m) Their combined length was nearly 16,000 feet (4.9 Km).

Once the 1st two tunnels were in place, 2 cofferdams were constructed to isolate the construction site & protect it from flooding.

The internal tunnels, after being utilized for river diversion, were plugged with concrete approx. 1/3 of their length below the inlets & the outer tunnels were plugged approximately midway. The 2 (two) internal tunnels contained 30’ (9.15m) diameter steel pipes, which connected the intake towers in the reservoir with the penstocks to the power plant and the canyon wall outlet works. The downstream halves of the two outer tunnels were used for spillway outlets.

Dam Structure

As in any construction project, the dam’s base was a major factor in building an enduring structure. This is mandatory for men to excavate the mud & muck at the river bottom. With the aid of power shovels, the men removed over half a million cubic yards (382,300 CuM) to reach bedrock 40 feet (12m) below.

Rather than being constructed as a single block of concrete, the dam was built as a series of individual columns varying in size from about 60 square feet (5.6 m2) at the upstream face of the dam to about 25 square feet (2.3 m2) at the downstream face. The reason that the dam was built in this fashion was to allow the tremendous heat produced due to the heat of hydration to dissipate quickly. Engineers of the Bureau of Reclamation calculated that if the dam were constructed in a single continuous pour, the concrete would have got so hot that it would have taken 125 years for the core concrete to cool to atmospheric pressure. The produced stresses would have caused the dam to crack & crumble away.

It wasn’t enough to place small quantities of concrete mix in individual columns. Each form also consisted of cooling coils of a 1″ thin-walled steel pipe. When the concrete was first filled in, river water was circulated through these pipes. Chilled water from a refrigeration plant on the lower cofferdam was circulated through the coils to complete the cooling. As each block was cooled, the pipes of the cooling coils were cut off and pressure grouted at 300 psi (20 kg/cm2) by pneumatic grout guns.

To stop the hairline fissures between the blocks from weakening the dam, the upstream & downstream faces of each and every block were formed with vertical interlocking grooves; the faces turned toward the canyon walls with horizontal & vertical cuts. When the concrete was cooled, a cement and water mixture called grout was forced into these joints created between the columns by the contraction of the cooled concrete to form a monolithic structure.

Concrete

3,250,000 cu.yd. (24,84,950 CuM) of concrete were placed in the dam itself, and another million plus cubic yards (7,64,600 CuM) in the appurtenant works.

The initial concrete essential for the dam was mixed in a river-level mixing plant which was located approximately 3/4 of a mile upriver from the dam site. This plant supplies the concrete for the linings in the diversion tunnels and for the lower levels of the dam. It came into operation on March 3, 1932. The concrete was weighed into buckets, which were transported, to the site firstly by truck. Ultimately, the concrete buckets were transported through electric trains. For the first year of operation, nearly 400,000 cu.yd. (3,05,840 CuM) concrete produced at this plant went into the linings of the diversion tunnels. In the tunnels, the concrete buckets were shifted by a gantry crane, which ran on rails from one end of the tunnel to the other.

The firstly concrete was poured into the dam on June 6, 1933. The concrete was poured into the dam utilizing 4 and 8 cu.yd. (3 to 6 CuM) bottom dump buckets. All these buckets were shifted from the cars & lowered into place by overhead cableways. There was a total of nine of these cableways used to place the concrete. 5 of the cableways were connected to moveable towers, which permitted them to be repositioned to work on different parts of the dam when required.

As the height of the dam is rise, a new concrete mixing plant was built on the canyon rim. Fully automated, the hi-mix plant measured ingredients, mixed & dispensed the concrete. It was efficient in producing 24 cu.yd. (nearly 18 CuM) of concrete every three & a half minutes. The hi-mix plant was used to produce all of the concrete placed in the dam above the 992 feet (302 m) level.

In order to produce good strength concrete with minimum cement content, a very dry mix had to be used. There was very less time available to move the concrete from the mixing plant to the dam. If too much time was taken, the concrete would take its initial set in the dump buckets itself and would have to be chipped out by hand. Due to this reason, the men who operated the cranes, which moved the buckets into place, were some of the highest-paid workmen on the project, earning $1.25 per hour. As each & every bucket was dumped, 7 puddlers utilized shovels & rubber-booted feet to distribute the concrete throughout the form. Pneumatic vibrators ensured that there were no voids and that concrete was densely compacted.

Hoover Dam was the 1st man-made large structure to exceed the masonry mass of the Great Pyramid of Giza. The dam consists of enough concrete to pave a strip of 16’ wide & 8” thick from San Francisco to New York City. Greater than 5 million barrels of Portland Pozzolana cement & 4.5 million cu.yd. (34,20,000 CuM) of aggregate went into the dam. If the heat generated by the curing concrete could have been concentrated in an oven, it would have been efficient to bake 500,000 loaves of bread per day for 3 years.

The dam took the lives of 94 construction workers and 2 government employees were killed while working on the Hoover Dam. Specifically, 24 fell to their death, three drowned, ten died in explosions, five were electrocuted, twenty-six were struck by falling debris, twenty-six were struck by machinery or heavy equipment, one died in an elevator accident, and one died in a cableway hazard.

Hoover Dam – How It All Works

Hoover Dam is a part of the Bureau of Reclamation’s multipurpose projects on the Colorado River. These projects control floods, store water for irrigation purposes, and municipal & industrial use; and provide generation of hydroelectric power, recreation, and fish & resident for wildlife.

Lake Mead, a byproduct of Hoover Dam, with a storage capacity of 28,537,000 acre-feet (35000 million CuM), is the largest man-made lake in the United States. The reservoir stock the whole average flow of the river for 2 years. Lake Mead extends approximately 110 miles (177 Km) upstream toward the Grand Canyon. It also extends about 35 miles (53 Km) up the Virgin River. The width varies from several hundred feet in the canyons to a maximum of 8 miles (13 Km). The reservoir covers about 157,900 acres or 247 square miles (640 square km).

Although, recreation is a by-product, constitutes the main use of the lakes & controlled flows created by Hoover and other dams on the lower Colorado River today. Lake Mead is one of America’s famous recreation areas, with a 12-month period that attracts more than nine million visitors each year for swimming, boating, skiing & fishing.

The Hoover Dam Power Plant has 17 large generators and has a rated capacity of more than 2,000 megawatts. There are seventeen major turbines in the Hoover Power plant. Hoover Dam supplies the generation of low-cost hydroelectric power for utilization in Nevada, Arizona & California. Hoover Dam alone generates more than 4 billion kilowatt-hours a year – enough to serve 1.3 million people. From 1939-1949, the Hoover Power plant was the world’s biggest hydroelectric installation; with an installed capacity of 2.08 million KW, it is still one of the country’s largest. Through the sale of power & water, the Bureau of Reclamation has been able to return to the Federal Treasury the cost of its operations on the Colorado River.

Conclusion

The benefits provided by Hoover Dam extend to remote parts of this planet far beyond the arid regions of Southwest America. The lessons learned during the design and construction of the dam helped ensure the success of large dam projects throughout the world. The success of Hoover Dam has helped the construction of projects through which thousands of people who may never have heard of Hoover have benefited.

It is a monument symbolizing the courage and endurance of Engineers, workers and their families who came to this inhospitable desert in extreme conditions with temperatures often above 1200 Fern hit (490). It is important to remember that all was accomplished before computers were available to solve complicated equations and accurate calculations. This dam as a structure has very impressive statistics but the benefits it has given to mankind are much more than impressive. They are beyond comparison and cannot be quantified or measured. Hoover Dam is certainly an engineering feat and one of the most successful public works projects in History.

You must be logged in to post a comment.