Formwork Installation is one of the most cost-oriented and complicated works on-site, consuming considerable time. Many times accidents and serious damages during construction are caused due to unsafe or incorrect practices in formwork. Formwork is also responsible for the shape of the structure and surface finish and therefore it contributes significantly to the strength as well as durability of the concrete structure.

Checklist for Formwork Materials

Wood

Following checks are necessary to ensure satisfactory use of this material:

- Quantity (density, bending stress, horizontal shear and modulus of elasticity)

- The direction of gains and presence of knots

- Moisture content

- Size and shape

- Damage (edges, broken, splits, cracks, etc).

- Bending radii

Plywood

Following checks will be useful before using this material in formwork:

- Quality (shuttering type, bending stress, rolling shear & modulus of elasticity)

- Direction of grains

- Type (plain, moisture resistant, surface coated, etc.)

- Moisture content

- Thickness

- Weight per square meter

- Damage (edges, surface, etc.)

Steel

Check for Purpose made Formwork

- Quality (allowable bending stresses, allowable horizontal shear, modulus of elasticity)

- Compliance with physical and chemical properties

- Manufacturer’s test certificate

- Surface defects – rust, dents holes, bends cracks, cuts, etc.

- Weight per square meter (plate) or per RM (sections)

- Cross-sectional area, thickness, diameter, and other dimensions

- Section modulus, radius gyration, the moment of inertia

Check for Proprietary Formwork

- Quality of Material (strength, shape, thickness, other dimensions as per manufacturer’s manual)

- Compliance with the manufacturer’s instructions

- Load carrying capacity

- Inspection of each piece and periodic maintenance before use

- Bolting, splicing and sliding arrangements

- Welds on cleat angles of telescopic trusses and other welds

- Damage ( bends, cracks, dents)

- Yokes and fastening devices

- All threaded portions for damages or wear

- Availability of standard pins for adjustable steel props instead of non-standard nails, bolts or mild steel bars

- Top and bottom plates of adjustable props – Not deformed and at right angles to the prop axis ( important especially when props are at their maximum extension)

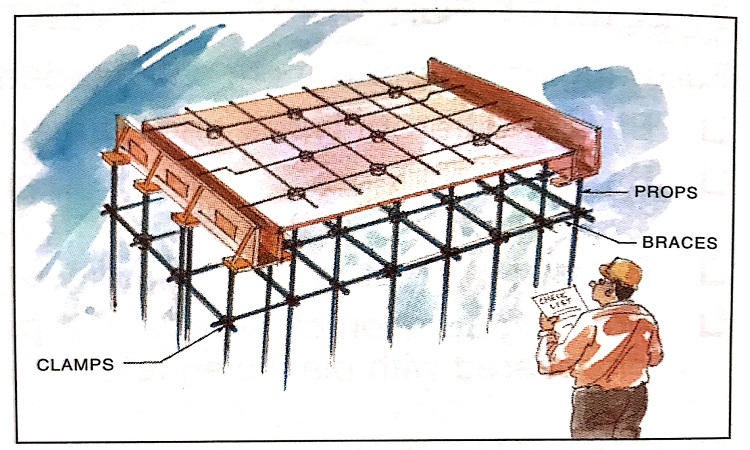

Checklist for Erection of Formwork

Following checks are necessary:

- All dimensions & levels correct eg. Depth of slabs, size of beams & columns.

- Alignments correct

- Height of slab from the floor below t soffit above

- Position of all fixtures, fittings, and fastenings on each panel in the right position

- Bearing area and thickness of washers used for tie bolts

- Tightening of all tie bolts and wall ties

- Timber packing, if any – intact after tightening of ties, bolts, wedges, etc.

- Quality of threads on tie bolts

- Cleanliness of formwork and application of proper quality release agent (mold oil)

- Cleanliness within the formwork (wooden shavings, nails, binding wire, dirt, etc. to be removed)

- All fill – in pieces and closure panels and closure marry with the main panels

- Plugging of all holes in formwork

- Inserts, blocking out pieces, boxes and bitterns securely fixed

- Locking devices such as nuts, bolts, brackets, etc. in the correct position

- Retractable bearer plates fully extended and adequately seated (telescopic floor truss)

- Cleat angles placed on strong support at both ends (telescopic floor truss)

- If telescopic floor truss in minimum span, then care to be taken during striking off the formwork

- Provision of the proper walkway, working platforms, and approaches

- Provision of guard rails

- Large prefabricated formwork panels provided with a spreader/lifting beam to prevent damage

- Levels of formwork while erecting

Checklist for Safe Practices in Formwork

Following must be checked to assure formwork:

- Design and working drawing of formwork

- Adequacy of construction loads for which formwork is designed

- Adequacy of the strength of all materials assumed in the design

- Limits on the rate of concrete pour and concrete temperature at the time of pouring

- Sequence and schedule of concrete pours

- Formwork detailed with dimensions, including pouring pockets, compaction openings, and cleanouts.

- Locations of expansion/construction joints

- Shoring and reshoring with braces and supports

- Adequacy of soil bearing values assumed

Checklist for Overall Safety in Formwork

Inspection checks of formwork necessary for overall safety:

- Entire formwork system with all details from bottom to top ensuring proper load transfer in a safe manner

- Safe working scaffolds, ladders, runways, ramps, and crossings.

- Maintenance of good housekeeping to keep the work areas and passages safe

- All peripheral edges and floor openings guards

- Sufficient workspace for each worker without overcrowding

- Safety training for all workers involved in formwork and concrete work must be given and practices re-examined

- Provision of adequate safety equipment such as helmets, safety belts, etc.

- Provision of power tools with safety features (checking & routine maintenance carried out)

- Installation of safe temporary electrical power cables in accordance with local Electricity Act requirements

- Formwork, rigging inserts, and connections checked for correct installation ( periodically examined for wear & correct positioning)

- All loose hanging forms removed during stripping works

- No loose materials stored on exposed floors, Tie-down or secure loose materials

- Exposed nails from all stripped timber bent down or removed

- Ties projecting into the work area removed or bent

- To counteract carelessness due to fatigue, additional supervision of work to be performed towards the end of the day or shift.

- Maintenance of safety against fire

- Inspect complete forming system from bottom to top in all details ensuring load transfer in a safe manner

- Horizontally placed tubular bracing should not be vertically loaded

- Channel and “I” beam supports on cut-outs placed correctly below the props

Checklist for Props or Shores

Most of the formwork failures are attributable to inadequacies of props and shores. The following items therefore need proper inspection:

- Isolation and rejection of defective props

- Vertically off all props

- Height of all props

- Spacing between props

- Rejection of props without bearing plates

- Top and bottom plates at a right angle to the prop

- Runners above props are not more than 25 mm off-center

- Deformation in inner or outer prop tubes (important when the adjustable prop is at maximum length)

- Props on firm bearing / hard strata

- Strata below the prop and the area adequacy of the mudsill below the prop

- Improvement of soil below the props by compaction and by proper drainage of the surface water

- Ground-level concrete slab completion before erecting props for supporting the slab above

- Avoid wooden props or bamboo especially for heights more than 3 m

- Firm locking and safe nailing of clamps on adjustable props

- Complete fixity and lateral stability at the joint between props when one prop is placed on top of another

- Pins on props or welded frames installed and props/frames fully braced

- Proper bearing below the stringers and joists at point of supports

- Stringers (runners) firmly attached to the props or bridged to prevent overturning from lateral forces

- Deep joists laterally braced to prevent overturning

- Extra bracing to resist lateral forces on a sloping beam or slab forms

- Localized concentrated loads prevented unless forms specifically designed to take such loads

- Columns poured at least one day ahead of the slab for lateral stability

- Propping system connected with the columns for lateral stability by extending the braces and yoking the columns with the braces

- Construction loads not placed on a freshly cast slab or beam while deshuttering ( removal of props) is in progress

Checklist for Wall Forms

The following needs to be checked for wall forms:

- Lateral bracing support firmly attached to the forms and at all points of support

- Blockout / stop end braced to resist lateral and vertical loads

- Form panels checked for adequate tying and bracing

- Corners of forms tied to prevent bulging or spreading

- Length, strength, and spacing of wall ties

- Spacing between wales

- Joints on wales staggered from one tier to the next

- In double member wales, one member left continuous across the form ties location

- Wall ties and bolts tightened properly

- In double member wales, both wales have similar depths

- Adequate lap provide between forms and previously cast concrete and all hardware firmly secured

- Ensure that grout leakage does not occur at joints between old concrete and joints between panels and panels above the old concrete

- Experienced supervision while installing the wall forms and while placing concrete

Checklist on Formwork during Concreting

The following checks and proactive actions are necessary:

- Before concreting starts to ensure proper access for workers involved in placing, compacting and finishing concrete

- Presence of experienced supervisor keeping a continuous watch for any hazardous situation

- An adequate supply of spare props, bolts, clamps, wedges, and skilled workers at the site

- Alignment, camber, level and plumb maintained while concreting is in progress

- Effective depth between the bottom and top reinforcement not disturbed

- Cover of concrete around reinforcement steel maintained as specified in working drawing

- Grout loss due to movement at joints & corrective action taken against it

- Loosening of wedges and fixings due to vibrations transmitted to the formwork and corrective action against it

- Spilled concrete/grout cleaned immediately

- All wooden spreaders, to hold vertical form faces apart, removed it after placing concrete

- Wooden members for creating pockets, removed before concrete sets fully

- During concrete pouring sequence avoid eccentric loading

- Prevention of heaping of concrete

- Prevention of high impact drops from concrete buckets

- Rate of concreting within permissible limits as shown on working drawing or as assumed while designing the formwork against lateral pressures

- The proper bond between layers of concrete

- Concrete is placed in layers, by ensuring that needle vibrator while vibrating the top layer of concrete also penetrates the lower layer of concrete

Checks on Striking (Stripping) Formwork

The following checks are necessary:

- Layout and formwork design such that smooth striking of formwork in a sequential manner is possible

- Strength of concrete capable of taking weight and construction load on it

- Removal time to be ascertained depending on the grade of concrete mix, size, shape, and span of the member and its rate of gain of strength, type of cement, weather conditions and ambient temperature and extent of curing executed

- Removal time in line with those specified in code of practice

- At the time of removal of side form, edges and corners not damaged

- Tiles, clamps, and wedges loosened and removed gradually

- Props in case of slabs and beams removed in stages from mid-span working outwards

- Nuts, bolts, clamps, wedges collected in a box and not dropped carelessly

- Use of crowbars to prise open forms avoided

- Formwork prised loose using wooden wedges

- Formwork carefully lowered and not damaged and dropped

- Panel faces should be carefully lowered and removed without them hitting the scaffold projections

- Panels placed on the leveled surface after removal

- Nail projection hammered down

- Cordoning off the area below the location where formwork removal is processed

- Presence of component crane operator and foreman

Check on Cleaning and Storage of Formwork

The following checks are necessary:

- Formwork as soon as it is removed, cleaned with a stiff wire brush

- Dirt, dust, stubborn bits of concrete or grout removed

- Ply and timber surface coated with a release agent before storing

- Steel form coated lightly with oil to prevent corrosion

- Damaged formwork stored out and repaired before storage

- Nail holes, depressions repaired with suitable materials and lightly rubbed down to give a smooth surface

- To protect the surface of panels, stored face to face

- Panels and plywood sheets stored on a horizontally leveled floor

- Storage area protected from moisture and rain and well ventilated

- All formwork materials stacked off the ground

- Loose wailing, soldiers (struts), etc. stored with relevant panels after numbering for a proper match when reused

- Nuts, bolts champs, pins, wedges, keys, and ties stored in separate bins or boxes