Cold weather is determined as a period when for greater than three consecutive days, the undermentioned conditions exist:

- Average daily air temperature is less than 5oC.

- Air temperature isn’t greater than 10oC for more than 1/2 of any 24-hour period.

The average daily air temperature is the average of the highest temperatures and the lowest temperatures occurring during the period from midnight to midnight.

Cold weather according to this definition usually begins during fall and usually continues until spring.

IS: 7861 (Part II) defines cold weather concreting as any operation or activity of concreting done at around 5oC atmospheric temperature or below.

What Happens When Concrete Freezes?

Pore water in concrete begins to freeze around -1oC.

- As some water freezes, the ion concentration in the unfrozen water rises, further depressing the freezing point.

- At around -3oC to -4oC, enough of the pore water will freeze so that hydration will completely stop depending on the extent of hydration, and thus the strength of the concrete, the forces generated by the expansion of ice may be detrimental to the long term integrity of the concrete.

Why Do Cold Weather Pose Problems?

Concrete in cold weather faces two major tribulations:

- Concrete can freeze before it acquires strength which breaks up the matrix.

- Concrete sets more slowly when it is cold and sets very slow below 10oC. Below 5oC, the hydration reaction basically stops and the concrete does not gain strength.

The temperatures referred to above are concrete temperatures and not air temperatures. Therefore when it is cold, the concrete needs to be protected until it can handle the temperature on its own. The general rule is that once the concrete has gained strength to about 3.5 MPa, it is all right. The magical thing that happens is that simultaneously as the concrete achieves 3.5 MPa compressive strength, hydration of the cement has consumed enough of the water in the original mix so that even if it does freeze, there isn’t sufficient water left in the pores that can damage the concrete. With most concrete, even at 10oC, this takes place on the second day.

To help concrete reach the 3.5 MPa strength, two things can be done in cold weather. The mix can be changed to get it to set more quickly or shield the concrete from the cold or both.

Requirements of Plastic Concrete Affected By Cold Weather

- In its “plastic” state, concrete will freeze if its temperature falls below 4oC. If concrete freezes at this state, the potential concrete strength can be reduced by over half adversely affecting the durability.

- Concrete should be protected until it attains a minimum of 3.5 MPa which could be about 2 days after placement if the maintained temperature is 10oC.

- Effects of low concrete temperatures:

Lower temperatures have a series of effects on the behavior of concrete:

- Considerable ultimate strength decreases up to 50% can occur if concrete is frozen within a couple of hours after placement or before it achieves 3.5 N/mm2 compressive strength.

- Setting time increases delaying the finishing of concrete.

- Bleed water takes longer to evaporate.

- Concrete takes longer to harden and gain strength.

- Formwork removal gets delayed.

- Delay in progress of construction due to lower strength gain.

Objectives of Cold Weather Concreting

The objectives of cold weather concreting are given below:

- Prevent damage to concrete because of freezing at early ages.

- Assure that concrete develops the necessary strength for the safe removal of forms.

- Limit rapid or quick temperature changes in the concrete to prevent thermal cracking.

- Provide protection consistent with the intended serviceability/functionality of the structure.

For each 10oC reduction or degradation in concrete temperature, the setting time of the concrete doubles, thus increasing the amount of time that the concrete is vulnerable to damage on account of freezing. It is important to note that warm concrete placed on cold sub-grade will lose heat & its temperature will drop.

It is further important to understand that even if after the concrete has reached the specified 28-day strength the structure may have got damaged due to inadequate curing and protection.

Concrete that is protected or sheltered from freezing until it has attained a compressive strength of a minimum of 3.45 N/mm2 will not get damaged by exposure to a single freezing cycle.

Properly cured concrete and properly protected concrete will mature to its required strength despite subsequent exposure to cold weather. For cold weather concreting no external supply of moisture is important except in heated, protected enclosures.

Principles Concerning Cold Weather Concreting

- Concrete that is protected from freezing or protected from sheltered from freezing till it has attained a compressive strength of at least 3.5 N/mm2 will not be damaged by exposure to a single freezing cycle.

- Concrete that is sheltered as stated above will develop to its full strength even if it is subsequently exposed to cold weather. No extra protection is required unless a particular strength is required be attained in less time.

- Protection at temperatures above 10oC in necessary in case a specified concrete strength is required to be achieved in a few days or weeks.

- Little or no external supply of moisture is necessary for curing during cold weather except within heated protective enclosures.

- Under specified conditions, calcium chloride should not be used to hasten setting and hardening due to chances of metal corrosion in concrete or other undesirable effects.

Temperatures given above are not exact values for all situations and the user needs to exercise discretion as far as the primary intent and adequacy of each particular circumstance require.

General Provisions for Cold Weather Concreting

The following requirements are necessary:

Planning

The contractor, supplier, specifier, producer, laboratory, and other interested parties need to hold a pre-construction conference to clearly and precisely define how cold weather concreting methods will be used.

Appropriate planning procedures to protect fresh concrete from freezing and maintain temperatures above the suggested minimum values are required to be made well in advance before freezing temperatures are expected to occur. The work site must be ready with the equipment and materials before the occurrence of cold weather and not after the concrete has been placed and the temperature begins to approach the freezing point.

Protection during Fall and Spring

During fall and spring when heavy frost and freezing is likely to occur at the site and which are periods not defined as cold weather, all concrete surfaces must be protected from freezing for the initial 24 hours after placement. This shields the concrete from harm due to freezing at an early age. When the concrete is air-entrained and properly cured, the ultimate strength and durability of the concrete remain unaffected.

Safeguarding from freezing during the first 24 hours is no assurance of a satisfactory rate of strength development especially when followed by cold weather. Protection and curing have to continue long enough at a temperature far above freezing to generate the strength required for removal or structural safety.

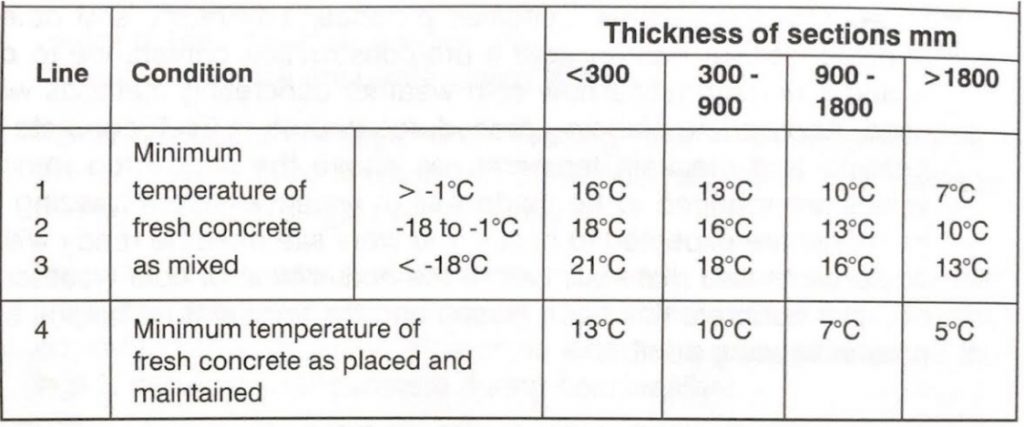

Concrete Temperature

The temperature of concrete at the time of placement should always be near the minimum temperature as per the given table no 1. Placement temperatures should not be higher than these minimum values by more than 11oC. Cold weather must be used as an opportunity to place low-temperature concrete. Concrete that is placed at low temperatures 5oC – 13oC is shielded against freezing and requires a long time curing, develops a higher ultimate strength and greater durability. Henceforth it is less subject to thermal cracking than similar concrete placed at higher temperatures. Placement of concrete at higher temperatures might accelerate finishing in cold weather weakening the long-term properties. There is no advantage in using fresh concrete temperatures greater than 21oC.

Temperature Records

The actual temperature at the surface of the concrete decides the effectiveness of protection irrespective of the air temperature. It is hence desirable to monitor & record the concrete temperature. Temperature recording and monitoring must take into account the undermentioned:

- Corners and edges are more vulnerable to freezing. Their temperature should be monitored to evaluate and verify the efficacy of the protection provided.

- Records of the time, Records of the date, outside air temperature, temperature of concrete as placed & weather conditions must be maintained. Temperatures of concrete and the outdoor air should be recorded at regular intervals of time but not less than twice per 24-hour period. Temperature at various points within the enclosure & on the concrete surface, corners and edges should be included in the records. A satisfactory number of concrete temperature measurement locations to show the range of concrete temperatures should be there. Setting thermometers against the concrete under temporary covers of heavy insulating material till constant temperatures are indicated or shown will achieve satisfactory accuracy & greater flexibility of observation.

- It is necessary to record maximum and minimum temperature readings in each 24-hour period. Data should show the temperature history of each section of concrete cast. It is advisable to measure the temperature of concrete at more than one location in the section cast and use the lowest reading to represent the temperature of that section. Expendable thermistors or thermocouples cast in the concrete may be used to monitor internal temperature of concrete to ensure that excessive heating does not occur.

Heated Enclosures

Strong windproof and weatherproof heated enclosures to maintain proper temperatures at corners, edges, and thin sections must be used. Combustion heaters should be vented to the outside to prevent carbonation. Fresh concrete surfaces are exposed to carbon dioxide (CO2) by use of combustion heaters that exhaust flue gases into an enclosed area can get damaged by carbonation of the concrete. This can cause soft surfaces or surface crazing depending on the carbon dioxide concentration, concrete temperature, and relative humidity.

Fire can destroy the protective enclosures and also damage the concrete at any age. Adequate fire prevention measures should be enforced. At a very early age, further damage can occur by subsequent freezing of the concrete before new protective enclosures are provided.

Exposure to Freezing & Thawing

In the likelihood of concrete getting exposed to cycles of freezing and thawing during saturation, it should be properly air-entrained even though it is not exposed to freezing and thawing during service. The water-cement ratio should not exceed the recommended limits and the concrete should not be allowed to freeze and thaw in a saturated condition before developing a concrete strength of 24 MPa. New sidewalks and other flatwork exposed to melting snow during the day and freezing during the night should be air-entrained and shielded from freezing until strength of at least 24 MPa has been attained.

Concrete Slump

All else being equal, low slump and/or low water/cement ratio mixes are particularly desirable in cold weather for flatwork. This reduces bleeding and decreases setting time. Concrete with a slump lower than normal is especially recommended for flatwork in cold weather as bleeding of water is minimized and setting occurs earlier. Bleed water may remain on the surface for a period sufficiently long enough to interfere with proper finishing. If the bleed water is mixed into the concrete during trowelling, the surface will have lower strength and may become prone to during and subsequent freeze-thaw damage if exposed. Hence during cold weather, the concrete mix must be designed so that bleeding is minimized. Bleed water present on the flatwork should be skimmed off before trowelling with the help of a hose or rope.

The temperature of Concrete During Mixing and Placing and Healing of Materials

Placement Temperature

Concrete mixing temperature should be controlled so that when the concrete is placed, its temperature does not fall below the recommended values. Lower minimum placement temperatures are advised for larger concrete sections. Higher temperatures need more mixing water, increase the rate of slump loss, could cause quick setting, and increase thermal contraction. Rapid moisture loss can occur from surfaces exposed to cold weather as the surrounding cold air gets heated due to the warm concrete thus reducing its relative humidity. Hence the temperature of concrete when placed should be kept as close to the recommended value as possible.

Mixing Temperature

The concrete temperature during mixing should be increased as the ambient temperature decreases to counterbalance the heat lost in the time between mixing and placing. As it is difficult to heat aggregates uniformly to a preset temperature, the mixing water temperature can be easily adjusted by blending hot and cold water to achieve a concrete temperature within 5oC of the required temperature.

Heating Mixing Water

Availability of mixing water at a regulated, consistent temperature and in adequate quantity to avoid fluctuations in concrete temperature from batch to batch is an important factor.

Temperature fluctuations may result in variable behavior of individual batches as the temperature of concrete affects the rate of slump loss which could affect the performance of admixtures. when very hot water prematurely comes in contact with concentrated quantities of cement, flash set and cement balls in truck mixers can occur.

If water above 80oC is used, the order of ingredients blended may need to be adjusted. Hot water and coarse aggregates may be added ahead of the cement and stopping or slowing down the addition of water whilst cement and aggregates are loaded could help. Alternatively, two mixing cycles can also be adopted. The first cycle of adding hot water and mixing with aggregates with frozen lump followed by the second cycle wherein cement is added with chemical admixture.

Heating Aggregates

Seasonal variations must be taken into account as average aggregate temperatures can be higher than air temperature during autumn whereas, during spring, the reverse may occur. When air temperatures are below 4oC, it is necessary to heat the aggregates. Aggregates that are free of ice and frozen lumps require only the mixing water to be heated to get the desired temperature of concrete during mixing. When the mixing water is heated to 60oC, it is rarely necessary to heat aggregates to temperatures higher than 15oC. When the coarse aggregate is dry & free from frost, ice, and frozen lumps, adequate temperatures of freshly mixed concrete can be achieved by increasing the temperature of only the sand which rarely has to be above 40oC if mixing water is heated to 60oC.

Since aggregates occupy the largest volume as compared to all other materials, an increase in the temperature of aggregates helps greatly increase the concrete temperature at the time of placing.

Steam Heating Aggregates

The most thermally efficient method to heat aggregates is liberating steam jets in aggregates. Circulating steam in pipes is suggested for heating aggregates. Aggregates may be thawed or defrosted by heating them carefully over culvert pipes in which fires are sustained. At the point when aggregates are heated or thawed by circulating steam in pipes, the surfaces of aggregates that are exposed or uncovered should be covered with canvases or tarpaulins to maintain a uniform distribution of heat as also to avoid the formation of ice crusts. Steam jets liberated in aggregates are likely to cause troublesome moisture variation. When steam is confined in a pipe heating system, difficulties from variable moisture in aggregates are prevented but the probably of localized hot dry spots gets increased. Wear and tear, corrosion of steam pipes in aggregates will cause leaks that may lead to similar moisture variation problems caused by steam jets. Inspection of pipes and replacement regularly is recommended.

When it becomes necessary to thaw large quantities of very low-temperature aggregates, steam jets can be used to provide the required heat. Thawing must be done ahead of batching to attain equilibrium in temperature and moisture content. After completing thawing, steam supply can be decreased to the minimum which will prevent further freezing & lessen the difficulties arising from variable moisture content. Under such conditions, mixing water control should be done on an individual batch adjustment basis. Dry hot air as an alternative to steam has been used to keep the aggregates ice-free.

Overheating of Aggregates

Aggregates should be heated to the extent that ice, snow, and frozen lumps are done away with. Normally, 76mm frozen lumps will survive mixing and remain in the concrete after placing. Overheating should be avoided so that spot temperatures do not exceed 100oC and the average temperature does not exceed 65oC when aggregates are added to the batch. Materials should be uniformly heated since substantial variation in their temperature will considerably vary the water requirement, air entrainment, rate of setting, and slump of the concrete.

Preparation before Cold Weather Concreting

The temperature of Surfaces in Contact With Fresh Concrete

Preparation for concreting means ensuring that all surfaces that will be in contact with newly placed concrete are at temperatures that cannot cause early freezing or prolonged setting of the concrete. Normally, temperatures on these contact surfaces, including sub-grade materials need not be higher than a few degrees above freezing say 2oC, and not more than 5oC higher than the minimum placement temperatures.

Metallic Embedments

The architect/engineer must determine whether the surface consists of large embedments that can face problems. In case heating is required, the heating process should not change the mechanical or metallurgical properties of the metal. A plan for heating needs to be submitted by the contractor to the engineer for approval.

Removal of Snow and Ice

The snow, ice, and frost must be removed so that it does not fill the space proposed to be filled with concrete. Hot-air jets can be used to remove frost, snow & ice from forms, reinforcement & other embedments. This must be done immediately before concrete placement to prevent re-freezing.

Condition of Subgrade

Concrete should not be placed on frozen sub-grade material. The sub-grade can be thawed by covering it with insulating material for a couple of days before concrete placement. In most cases, it may require the application of external heat. Site experiments will give you an idea about what combinations of insulation and time causes sub-surface heat to thaw the sub-grade material. The thawed material be re-compacted after heating.

Protection of Concrete against Freezing

Immediately after placing concrete, it must be protected to prevent early-age freezing. Provisions for covering insulating, housing, or heating newly placed concrete must be looked into before placement. The protection must be sufficient to achieve the recommended temperature and moisture conditions in all the sections of the concrete cast.

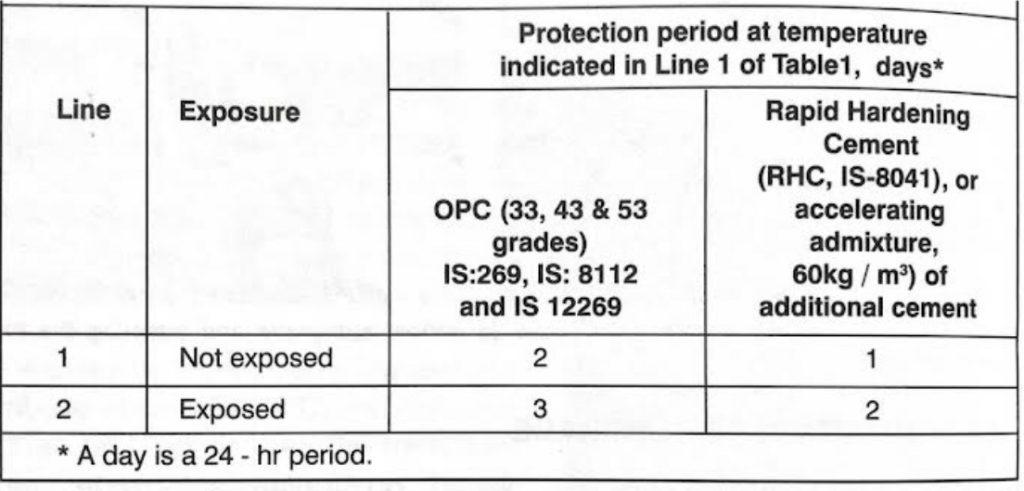

Below table no 2 displays the short periods of protection for air-entrained concrete when minimum protection requirements to prevent damage from one early cycle of freezing and thawing are needed.

These short periods are permissible only when there is adequate subsequent curing and protection to acquire the necessary safe strength for the specific service category as shown in table no 3 and the concrete is not subjected to freezing in a critically saturated condition. In case early age strength requirements are not achieved, it becomes necessary to extend the protection period beyond the minimum duration shown in table no 2.

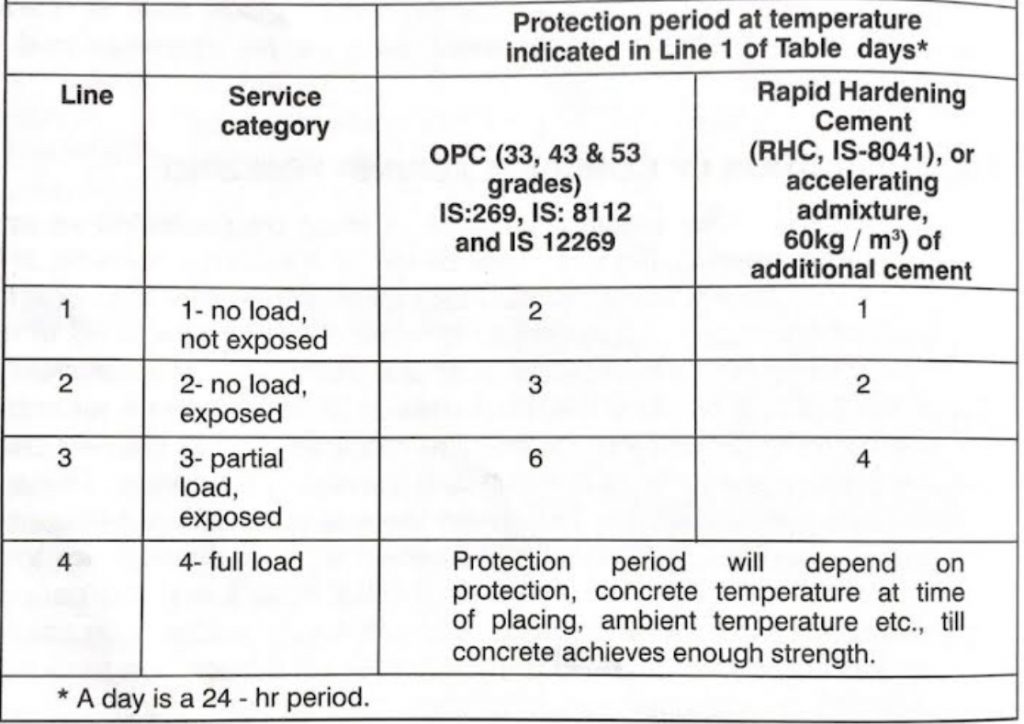

The extent of the Protection Period

The duration of the protection period depends on the type and amount of cement, whether an accelerated admixture is used as also the service categories which are explained hereunder:

No Load, Not Exposed

Includes foundations and substructures which are not subject to early load and on account of being buried deep within the ground or being backfilled, will undergo little or no freezing and thawing in service. The only protection against early age freezing is necessary for this service category.

No Load Exposed

Includes dams and massive piers that have surfaces exposed to freezing and weathering in service but do not have early strength requirements. Interior parts of such structures are self-curing whilst exterior surfaces continue to cure under favorable natural conditions. The only protection against early age freezing is necessary for this service category.

Partial Load Exposed

Structures exposed or uncovered to weather that could be subjected to small, early age loads compared with the design strengths have an opportunity for further strength development before application of design loads. In such cases, concrete must have the recommended length of protection.

Full Load

Includes structural concrete needing temporary construction supports to resist construction loads. Protection requirements that are recommended should be followed.

Stripping of Forms

During times of cold weather, forms that give protection assume great importance. Forms help to distribute the heat evenly in heated enclosures. If appropriate insulation or insulated forms are used, forms including those made of steel provide adequate protection without supplemental heating. Hence it would be advantageous to keep the forms in place for at least the minimum period of construction. In cases of economical construction that provide for the removal of forms at the earliest, they should be removed at the earliest, they should be removed at the earliest age that will not endanger the concrete.

Wedges used to separate forms from young concrete should be made of wood. Corners and edges do not get damaged during stripping if the concrete is strong.

Minimum time before stripping is determined by various job factors, type and amount of cement, other aspects of the concrete mixture, curing temperature, type of structure, from design and worker’s skills.

After removing the forms, concrete should be covered with insulating blankets or sheltered by heated enclosures for the recommended time.

When embedded electrical coils are used for internal heating, concrete needs to be covered with an imperious sheet and heating should be continued for the recommended time.

Early removal of forms in the case of retaining walls, basement walls, or structures where one side is subjected to hydrostatic pressure while the concrete is still young, form ties can get dislodged creating channels through which water can flow.

Drop-in Temperature after Protection Removal

Concrete needs to be cooled gradually to minimize crack-inducing differential strains between the interior of the structures and the exterior of the structure. Gradually decreasing sources of heat or allowing insulation to remain till the concrete has reached equilibrium with the mean ambient temperature can be used. Sometimes insulated forms can cause problems in lowering the surface temperatures. Loosening of forms away from the concrete and covering with polyethylene sheets to permit circulation of air can solve the problem.

| <300mm | 300 to 900mm | 900 to 1800mm | >1800mm |

| 28oC | 22oC | 17oC | 11oC |

Temperature Differential

When protection is removed, a temperature differential may be permitted, through concrete should be cooled to ambient temperatures to avoid thermal cracking.

The table can be referred to decide the maximum allowable difference between the concrete temperature in a wall & the ambient air temperature. These curves compensate for the thickness of the wall & its shape restraint factor, which is represented by the ratio of wall length to wall height.

Removing Forms and Supports

Removing of forms and supports and placing and removal of reshores should be as recommended.

- In-place strength of concrete that is required to permit removal of forms and shores must be specified by the engineer/architect.

- Tests of field-cured concrete samples or of concrete in place should be made.

- Procedures for evaluating the results of concrete strength tests and the minimum strength required for form and shore removal must be specified.

- Results of all tests, records of weather conditions and other relevant information should be noted and used by the engineer/architect in deciding when to remove forms and shores.

- Re-shoring methods which is significant in formwork should be pre-planned and reviewed by the engineer. This is necessary so that large areas of new construction are not subjected to combined dead and construction loads in excess of their capacity as determined by the in-place concrete strength at the time of form removal and re-shoring.

Covering after Placement

Tarpaulins or other freely movable coverings supported on wooden horses or another framework must closely follow the finishing of the concrete. Tarpaulins should be arranged to allow free circulation of heated air on the top as well as the bottom of the slab if exposed. Freezing can also be prevented by layers of insulating material placed directly on the concrete which is more important in the case of lightweight structural concrete.

Temporary Removal of Protection

Housing and enclosures must be left in place for the recommended protection period. Sections can be temporarily removed to allow placing additional forms of concrete but this should ensure prevention of freezing of the previously placed concrete is in their final position. The time during which protection is temporarily removed should not be counted as part of the protection period. The time lost from the required period of protection should be made up with twice the number of lost degree hours before protection is discontinued.

Power blankets/Insulating Blankets

They are electrically heated blankets used for protecting concrete in cold weather, heating/thawing ground and embedments before concrete placement, and hastening the rate of cure and strength gain. Power blankets/insulating blankets are available in various sizes and powers as per individual requirements. Power blankets insulating blankets have the following advantages:

- Heat and protect concrete

- Accelerate curing and strength and strength gain

- Accelerate maturity gain with additional of heat

- Preheat rebar

- Save on cost of fuel