What is Slump Cone Test?

A Slump test or Concrete slump test is to determine the workability or consistency of the concrete mixture prepared in the laboratory or at the construction site during the progress of work. The concrete slump cone test is used for the measurement of a property of fresh concrete. The slump cone test is an empirical test that measures the workability of fresh concrete. More specifically, it measures the concrete consistency between batches.

The slump cone test for workability is the simplest test and is most often used at construction sites and must be carried out using the apparatus complying with IS 7320 – 1974.

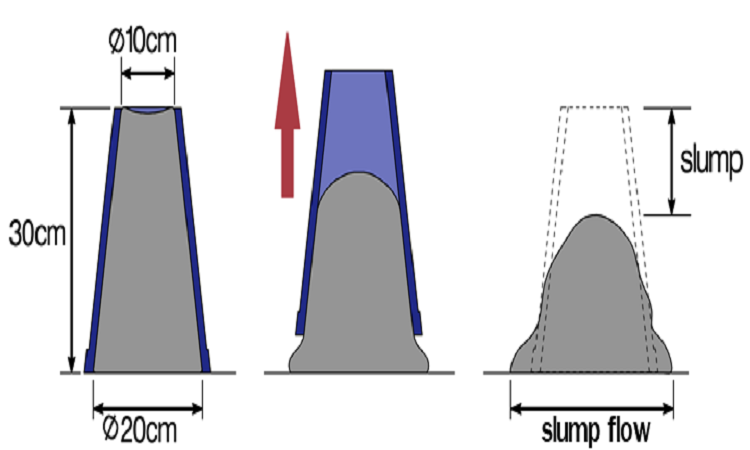

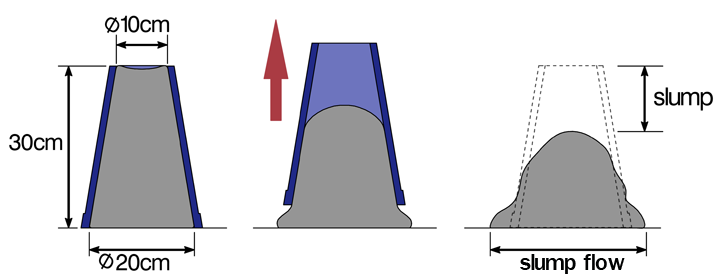

In the Slump test, the distance that a cone full of concrete slumps down is measured when the cone is carefully lifted from around it. The concrete slumps can vary from zero for dry mixes to complete collapse for very wet and lean mixes.

The accuracy of the slump cone test is generally limited to about 25 mm of the intended value when the workability of each batch is compared with earlier batches.

Equipment

The following equipments are required to carry out the slump test:

Standard Slump Cone

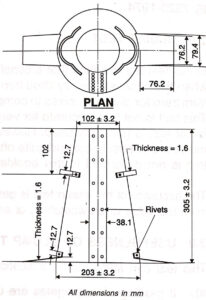

A standard slump cone – 300 mm (12 inches) height, bottom diameter of 200 mm (8 inches), and top diameter of 100 mm (4 inches). The mold must be provided with foot pieces and handles similar to those shown in the figure. The mould can be either with or without a seam. The interior of the mould shall be relatively smooth, and free from dents/projections.

Tamping Rod

A steel tamping bullet head (rounded shape) rod of 16 mm (5/8 inch) diameter, 600 mm (2 ft.) long.

Base Plate

A waterproof hard base plate with or without clamping arrangement. The clamping arrangement shall be such that it can be fully released without movement of the mould.

Scoop

Steel Float

Steel Ruler

Cleaning rags or cheese cloth

It is extremely important to clean all equipment after they are used and all equipment must be stored in a covered store and not left lying about on open site.

Usefulness of Slump Test

Slump test can serve as an indication for three factors:

- If the grading of aggregates is uniform it will indicate the variation of water content or water/cement ration.

- If surface moisture of fine aggregates is constant and the amount of water added to the mix is accurate then it will indicate variation in grading or variation in batching of cement or aggregates.

- If the cohesiveness of the concrete mix for particular workability is not adequate, due to inadequate concrete mix design and batching, the concrete cone will collapse or shear off.

Frequency of the Slump Test

It is important to do a slump test preferably in the first batch as soon as the concreting work starts. This is necessary so that the correct water addition is finalized to give the required workability. Thereafter this slump test is performed whenever the mix does not seem to be right and adjustment of water is desirable.

Slump cone test is also necessary for every batch of concrete sampled for cube test so that in case of cube failure some conclusions can be drawn whether the mix had higher W/C or in other words it had more workability than that of the recommended mix.

The slump cone test must be taken as soon as possible at about the same time after mixing.

Sampling

It is necessary to take proper samples which must be representative of the batch which is to be tested.

- The sample should be taken as concrete is being discharged from the mixer or ready-mix truck.

- The sample should be collected in at least four equal increments or parts. The first sample should be taken after one-fifth of the batch is discharged.

- The parts of samples are best taken using a sampling scoop through and across the stream of concrete flow from the mixer chute. Alternatively, a bucket can be used. Shovels are not recommended as it is likely that larger size aggregates may roll of causing the sample to be non-representative.

- The various sample parts are dumped in a wheelbarrow or bucket or platform depending on the tests to be made from each sample. Generally, cubes are also cast from the same sample.

- If the concrete mix sample is to be taken from a truck, dumper, or buggy or from a heap that has been just unloaded for placing, then it is necessary to take parts of the sample from at least six different locations using a shovel or scoop. The sample parts should not be taken from the top surface of the heap. It should be taken well below the top surface. It is also important to avoid taking samples from the lower edges of the heap as generally coarse materials roll down and will not give a representative sample.

- All parts of the sample must be thoroughly mixed together in the wheelbarrow. If collected in a bucket it must unload on the platform or non-absorbent steel tray (with edges high enough to prevent some portion of concrete mix to fall off or flow out) and then thoroughly mixed.

Procedure for Slump Test

The following procedure is required to be followed:

- Clean the internal surface of the cone and top surface of the base plate.

- Stand the cone on the base plate and stand with your feet on the footrests or clamp the cone firmly with the base.

- Use the scoop to fill the cone to about one-fourth of its height and tamp this layer of concrete exactly 25 times using the tamping rod.

- Add three further layers of about 75 mm height each, rodding each layer exactly 25 times allowing the rod to penetrate into the layer below.

- After rodding, the top layer makes sure that there is a slight surcharge of concrete at the top.

- Use the steel float & strike off the surplus concrete at the top.

- Clean the cone and base plate without disturbing the foothold or clamping device.

- Hold the cone handles firmly pushing downwards and release the foothold or clamps.

- Hold the cone handles & carefully lift the cone straight up till such time concrete is released from within the cone. The concrete slumps.

- Turn the cone upside down and place it close to the slumped concrete on the base plate.

- Reset the tamping rod on the inverted cone fully across the top so that it reaches over the slumped concrete.

- Using a steel ruler measure from the underside of the rod to the highest point of the concrete. If the distance is said 75 mm, the concrete slump will be 75 mm. accuracy of the measurement should be within 5 mm.

Acceptance Criteria for Slump Test in Ready Mixed Concrete

Before unloading the entire load, it is the essential that slump test is taken from the concrete from the transit mixer. The sample is taken in a similar manner as described in the sampling.

As Practiced in UK

- If the slump is within ± 25 mm of the required slump the load is acceptable.

- If the slump is not within ± 25 mm of the required slump further sample from the next half cubic meter discharged and repeat the test.

- If the slump of this second sample is within ± 25 mm of the required slump the load should be accepted.

- If the slump of this second sample is not within ± 25 mm of the required slump, the concrete load is rejected.

As Practiced in USA

- When the project specifications for slump are written as a “not to exceed” or “maximum” requirement:

Specified Slump

If 76 mm or less If more than 76 mm

Plus tolerance 0 0

Minus tolerance 38 mm 63 mm

This option is to be used only if one addition of water is permitted on the job provided such addition does not increase the water/cement ration above the maximum permitted by the specification.

- When the project specifications for slump are not written as a “not to exceed” or “maximum” requirement:

Tolerances for Nominal Slumps

For Specified Slump of Tolerance

51 mm & less ± 13 mm

51 mm to 102 mm ± 25 mm

More than 102 mm ± 38 mm

- Concrete shall be available within the allowable range of slump for a period of 30 min starting either on arrival at the job site or after the initial slump adjustment whichever is later. The first and last ¼ CuM discharge are exempted from this requirement.

Types of Slumps

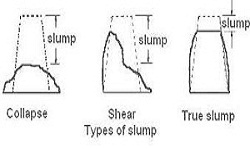

The slumps can be generally classified into three types.

- True Slump: When the concrete just subsides retaining its shape.

- Shear Slump: When the top half of the concrete cone shears off and slides down on one side in an inclined plane.

- Collapse Slump: When concrete does not subside but collapses completely losing its shape.

If the shear slump is obtained one more test should be taken for concrete workability. If this also shears and does not come true then it is due to the non-cohesiveness of the concrete mix. The design mix must be reviewed. Such concrete will segregate very fast while transporting, placing, and compacting and is likely to cause porosity and durability problems.

Similarly collapsed slumps are also not desirable and can happen when the mix is too wet and non-cohesive. Such mixes will also segregate very fast while transporting, placing, and compacting and are likely to create serious porosity and durability problems.

Reporting

A slump test can be separately reported or reported along with cube test results.

The following must be recorded.

- Date of test.

- A batch number from where the sample was taken.

- A slump in “mm”.

- Type of slump observed if not “true”.