The compressive strength of the concrete cube test provides an idea about the characteristics of concrete. By this compressive strength test judge that whether concreting has been done properly or not. Concrete compressive strength for general construction varies from 15 MPa to 30 MPa and higher in commercial and industrial structures.

The compressive strength of concrete depends on many factors such as water-cement ratio (W/C ratio), cement strength, quality of concrete materials, and quality control during the production of concrete, etc.

Purpose of the Test

The main purpose of carrying out this test is given below:

- The compressive strength of the cube is an indication of the potential strength of the concrete mix, from which it is sampled.

- It helps in determining whether the correct mix proportion of various materials was used to get the desired strength.

- The variations in results obtained at the site, from time to time, for a particular grade of concrete can help in determining the quality control exercised, and uniformly of concrete produced.

- It helps in determining the rate of gain of strength of the concrete sample if cubes from the same sample are crushed at different periods of time.

- It helps in determining the time of taking the concrete structure into service or the time of removal of formwork.

The cube strength does not necessarily indicate the strength of concrete in the finished concrete structure as it does not take into account subsequent steps such as transporting, placing, compacting, finishing, and curing.

Sampling

Samples from which the test specimens are moulded should be representative of the concrete entering the structure and considerable care is, therefore, required during sampling.

The following points must be considered while sampling.

- Samples must be taken at random to get a correct assessment of the quality of concrete produced over a given period.

- It is recommended to fix, for each day, specific times at which samples will be taken from specific deliveries. The timing or deliveries can be changed each day to obtain concrete samples in a more random manner.

- The number of samples to be taken each day will vary depending on various criteria such as the number of concrete mixes utilized at the site, the quantum of concreting done utilizing one mix, specification and tender conditions, etc.

- Samples should not be taken from obviously extra wet or extra-dry concrete mixes unless such indicates occur at the time or in a delivery previously fixed for sampling.

- Frequency – The minimum frequency of sampling of concrete of each grade, as recommended in IS: 456, shall be in accordance with the following.

| Quantity of Concrete in the work cum (m3) | Number of set of samples |

| 1 to 5 | 1 Sample |

| 6 to 15 | 2 Samples |

| 16 to 30 | 3 Samples |

| 31 to 50 | 4 Samples |

| 51 and above | 4 Samples + 1 additional sample for each additional 50 m3 |

- Samples should be collected as the concrete is being discharged from a conventional mixer or transit mixer.

- The samples should be taken in at least four equal increments or parts. The first sample should be taken after one-fifth of the batch is discharged.

- The parts of samples are best taken using a sampling scoop through and across the stream of concrete flow out from the mixer chute. Alternatively, a bucket can be used. Shovels are not recommended as it is likely that larger size aggregates may roll off causing the sample to be non-representative.

- The various parts are dumped in a wheelbarrow or bucket or platform depending on the number of cubes to be made from the sample.

- The quantity of concrete generally required per cube mould is 3kg and 10kg for 100mm and 150mm size cubes, respectively. It is recommended that the entire sample must have at least 20kg concrete. The sample must be collected independently of the number of test cubes to be cast. However, as large a sample as possible should be taken.

- If the concrete mix sample is to be taken from the truck, dumper, or buggy or from a heap that has been just unloaded for placing, then it is necessary to take the parts of the sample from at least six different locations using a shovel and scoop. The sample parts should not be taken from the top surface of the heap. It should be taken well below the top surface. It is also important to avoid taking samples from the lower give a representative sample.

- All parts of the sample must be thoroughly mixed together in the wheelbarrow. If collected in the bucket they must be unloaded on a non-absorbent steel tray or platform, with edges high enough to prevent some portion of concrete mix to fall off or flow ou, and then thoroughly mixed.

- After remixing, concrete cube moulds should be filled up as soon as possible.

- If the slump of this second sample is not within ± 25mm of the required slump, the concrete load is rejected.

Equipments

The following types of equipment are required for casting concrete cubes for compression strength.

Cube Moulds

The cube moulds must be made up of only steel or cast iron. The cube moulds are usually made up of three parts. Two halves constitutes the vertical sides of the cube and base plate. The two vertical halves are bolted together and then fixed on the base plate by clamping. Precaution is required to be taken to ensure that all three parts are of the same manufactured assembly or unit.

These parts often get exchanged with parts of other cube units, and therefore, do not match each other, resulting in either leakage of cement slurry and/or incorrect shape and size of concrete cube.

The inside face of these units must be planed and machine finished to a high degree of accuracy. If the surfaces are not planed and are pitted or scratched, the concrete cube will not have a correct shape and will result in incorrect compression strength.

Similarly, all internal angles of the moulds must be at right angles and within ± 0.5 Deg. There are chances that either due to a mismatch of the three units or due to improper fixing or manufacturing defects, the internal angles may not come right, which could lead to incorrect cube test results. The distance between opposite faces shall be within ± 0.2mm.

All internal faces especially at the edges and joints should be clean and free from hardened concrete, mortar, or dirt. If cleaning is not proper the edges will not sit firmly or correctly, resulting in the shape of the concrete cube.

When assembling the moulds, the flange faces and contact surfaces of the bottom of the mould and base plate should be thinly coated with mould oil to prevent leakage during filling. It is recommended to use a thin layer of grease when concrete workability is very high. It is equally important to apply mould oil on all internal mould surfaces to prevent the adhering of concrete on the steel surface or to prevent damage to concrete when the moulds are being opened up.

Cube moulds should be well looked after. They must be cleaned after every use and oiled to prevent them from rusting while not in use for a longer period. Do not store cube mould in the open nor store them in an open form. All units must be bolted and clamped and store together.

Tamping Rod

The tamping rod shall be a steel bar of 16 mm diameter and 600 mm long, with bullet head at the compacting end.

Spanners

Mould Oil

Scraper

Big Size Scoop to hole around 5kg concrete

Small Size Scoop to fill concrete in the cube moulds

A leveling Float

Wheel Barrow or Bucket

Cleaning Rags or Cotton Waste

Non Absorbent Tray or Steel Platform Crayon

Temperature Controlled Curing Tank

Damp Sacks or Polyethylene Sheeting

Procedure for Filling & Compacting Concrete in Cube Moulds

Filling of cube moulds must be done in three layers each approximately o 50mm thickness. The concrete must be placed using a scoop and the scoop should be moved around the top edges of the cube mould so that the symmetrical distribution of concrete is done in each layer as the concrete slides down from the inclined scoop into the cube moulds.

Each layer must be compacted fully either by using a tamping rod or by using a vibrator technique. If concrete is compacted by hand tamping, in 150mm mould, then 35 strokes are given per layer uniformly covering the entire surface especially the corners. If 100mm size of mould is used then each concrete layer must be hand tamped giving 25 strokes. Concrete in cube mould can also be compacted using vibration techniques.

The concrete should be compacted well in each layer leaving no chance for air entrapment within its mass. When air bubbles no longer appear on the top concrete surface it is understood that the concrete is fully compacted. Continue vibration or compaction until such time the concrete in the mould overflows and it is not possible to fill in more concrete.

Finally, trowel the surface level within the top of the mould. Identification mark, number, and/or date can be lightly scratched on the wet troweled concrete surface using a match stick or a scraper. Heavy-handed scratching using sharp-edged steel tools is not recommended.

Procedure for Identification, Curing, and Testing of Concrete Cubes

After finishing the concrete, the cube mould should be immediately covered with damp hessian cloth or transferred to a room where-in the relative humidity is 90% and the temperature is 27 ± 2oC.

- Coding/marking/identification should be such that the strength of the test sample can be easily co-related to the concrete mix used and the structure in which the concrete was poured. The concrete cube data sheet must be filled in properly.

- Strip the mould after 16 to 24 hours gently without damaging the edges or surfaces of the cubes.

- Submerge the specimen in the curing pond containing clean water till such time it is due for testing.

- Check the dimensions and weight of the specimen before testing.

- If NDT (Non-Destructive Testing) facilities are available, carry out the same on the cubes before they are crushed.

- Automatic (motorized) compression testing machines are preferred to manual compression testing machines on account of fewer chances of human error while leading.

Compression testing machines indicating the deviations from the rate of loading and having an arrangement to manually control the same during the tests are also available. Computerized compression testing machines automatically controlling the rate of loading are available in overseas countries and are most appropriate for accurate results. The compressive strength is calculated by dividing the failure load by the mean dimension of the section under the load.

Precautions Required to be Taken When Making Cubes

- Generally, unskilled workers are deployed for taking samples and casting cubes at the site. Often, workers taking cubes keep changing and due to lack of training and experience, inconsistent results are obtained. This can be controlled by utilizing only trained workers or technicians who are aware of the importance of testing and are also trained to take the concrete sample and cast the cubes correctly.

- Water in the curing pond must be fresh (replenished at least once in 7 days) and maintained at a temperature of 27 ± 2oC.

- The concrete cube should not be allowed to dry out either partially or fully.

- The level of water in the curing tank must be maintained in such a manner that all concrete cubes are completely immersed.

- The place of storage of the specimen should be free from vibration and should be within the temperature range of 22 to 30oC.

- It is very important to maintain the temperature around the concrete cubes when they are stored in the initial period of 24 hrs and later when they are being cured immersed in water. High temperatures will give higher strength indications and low temperatures will give lower strength indications in the initial period.

- While the specimen is being taken from the worksite to the laboratory, adequate care has to be taken for the protection against loss of moisture and damage.

- If the cube mould is too full after the final layer is completed, a float is used to push the concrete away from the sides to the center of the mould, and concrete (including coarse aggregates) is removed so that the cube mould can be leveled flush and troweled smooth. Never attempt to remove excess materials by scarping off the concrete at the surface.

- If the mix is a bit too wet, water will tend to rise to the top surface of the compacted concrete within the mould. To allow for this, the wet mix should be left 1 to 2mm above the top of the mould so that water will drain out and the cube can be finished and leveled without difficulty.

- Cube failures can occur on account of several reasons. Therefore, it is essential to carefully control and supervise the work so that cube failures due to such reasons are avoided.

Requirements of Compression Testing Machine

- The testing machine must be accurate, well-calibrated, and having capacity adequate enough to crush the concrete cube. Do not exceed 90% of the capacity of the machine while testing. If the cube does not crush, cut off the machine and use a machine of higher capacity.

- It is necessary to use a certified and tested proving ring.

- The testing machine shall be equipped with two steel bearing platens with hardened and smooth faces. The top platen shall be fitted with a ball seating in the form of a portion of a sphere which is concentric with the central point of the face of the platen.

- The bottom platen shall be plain and rigidly fixed on the bearing block. The top platen shall be such that the bearing face can be rotated freely and/or tilted through small angles in any direction.

- The bearing plates are generally circular and must be larger than the size of the concrete cube or the test specimen. They should not be out of the plane by more than 0.01mm at any point and should be maintained within the permissible variation of 0.02mm.

- The selection of capacity of the compression machine will depend upon the size of concrete cubes proposed to be used and the maximum concrete compression strength specified for the job after considering the variations expected on the higher side and cut-off load of 90% of the machine’s capacity.

Acceptance Criteria for Compressive Strength

The concrete shall be deemed to comply with the strength requirements, as per IS: 456, if:

- Every sample has a test strength not less than the characteristic value of concrete

- The strength of one or more samples though less than the characteristic value complies with the following condition

- The strength determined from any group of four consecutive test results compiles with the appropriate limits in column A of the given table.

- Any individual test results compile with the appropriate limits in column B of the given table.

For the individual test result requirements given in column B if the below table, only the particular batch from which the sample was taken shall be at risk. Where the mean rate of sampling is not specified the maximum concrete quantity that four consecutive test results represent shall be limited to 60cum.

| Specified Grade | Group of Test Results | A The mean of the group of test results exceeds the specified characteristic compressive strength by at least : (N/mm2) | B Any individual test result is not lower than the characteristic compressive strength less : (N/mm2) |

| M15 | Any consecutive 4 | 3.0 | 3.0 |

| M20 | Any consecutive 4 | 4.0 | 4.0 |

| M25 | Any consecutive 4 | 4.5 | 5.0 |

| M30 | Any consecutive 4 | 5.0 | 6.0 |

| M35 | Any consecutive 4 | 5.0 | 7.0 |

| M40 | Any consecutive 4 | 5.5 | 8.0 |

| M50 | Any consecutive 4 | 6.0 | 10.0 |

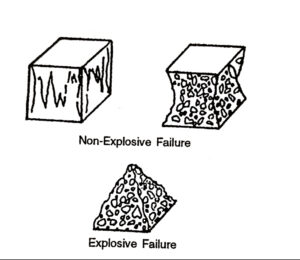

Modes of Failures

Usual

It involves equal cracking of all four exposed faces with little or no damage to the faces (top and bottom) in contact with the platens. Cracking is usually of a vertical zig-zag pattern.

At times four vertical faces of concrete cube break away leaving two truncated pyramids one inverted over the other. This is sometimes accompanied by an explosive sound.

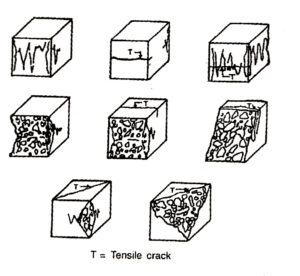

Unusual Mode

Concrete cubes may get crushed on one side or will develop a tensile crack on one face or more faces and fail.

These types of failures will give a lower indication of the compressive strength of concrete. These are usually due to defects associated with the testing machine. Faulty manual operation, the faulty placing of the cube, the faulty casting of the cube are also responsible for such defective failures.

Conclusion

Concrete cube testing and maintaining good cube test records do not mean quality control of concrete works. Often, the records show excellent cube results, but the actual quality of concrete is extremely poor. Concrete cubes are often cast with a stiffer mix (lower water to cement ratio) or using additional cement while actual concreting is done without any regards for water to cement ratio, which in turn influences the strength and durability of the structure. This approach has to change and the engineer must produce concrete of good durability and good strength for the structural members, rather than for keeping cube test records satisfactory.

Concrete will deteriorate and disintegrate and give indications of bad quality after a few years, even though concrete cube test results were found to be very satisfactory.

Conversely, a concrete structure constructed may be of good quality, but the careless procedure for sampling, casting, curing and testing of concrete cubes may give unsatisfactory results indicating low strengths. Careful monitoring of each and every step is necessary for this important test of concrete.