What is Crazing in Concrete?

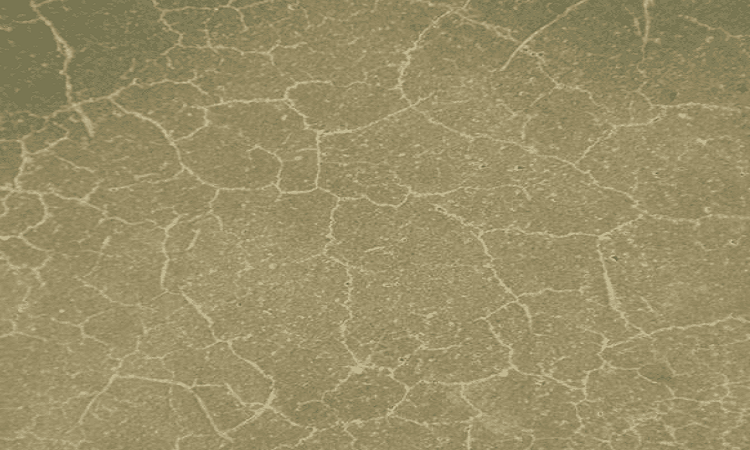

Cracking of concrete can occur both in plastic as well as in hardened stage. After several weeks or even earlier hardened concrete displays hairline, discontinuous, closely spaced surface cracking. This is called “Crazing”.

The use of smooth and impermeable formwork surface (steel, plastic) or over-trowelling of rich concrete mixes often results in the concentration of cement paste on the exposed surface. Due to inadequate curing and smooth finishing, high humidity gradients between the surface and the bulk of concrete are created. The cement paste which is exposed to drying conditions cracks easily. This causes drying shrinkage resulting in crazing.

Occurrence

Crazing occurs on smooth surfaces. It appears on hardened concrete surfaces after one to seven days period or much later. These cracks are particularly observed during the rainy season when the wet surface starts drying. The cracks appear in a crazy pattern generally 6 mm to 75 mm in length and a fraction of an mm in width and depth.

These cracks occur on the top surface of concrete slabs and give an impression as if the concrete surface is damaged. The cracks are superficial and will not cause structural weakness. However, they might open up and widen later and cause aggressive chemicals to enter and reduce the concrete structure’s durability.

Observations

Crazing is most often not visible to the naked eye. Generally, crazing has no fixed time of occurrence; it can be soon after the initial hardening of concrete or can become apparent after a few years.

However, generally, crazing becomes visible after dust particles get deposited in the cracks and considerable time has elapsed between the onset of crazing and its recognition.

It is found that some hair cracks formed due to drying of the top surface close when the surface becomes wet and cracks reopen when it dries once again.

Under certain conditions, cracks arising from the crazing of concrete may tend to close due to a “healing effect”. Its exact mechanism is not clearly understood, however, it is perhaps the hydrated gel from the body of the concrete that seems to be depositing on the surface, forming a ridge over the crack which later weathers off to leave a surface apparently free from crazing.

This phenomenon is similar to the healing of a fine cut on the human skin. Autogenously healing effect is usually associated with very fine cracks containing a reasonably good quantity of unhydrated cement. Healing of cracks can occur by continuous curing of the cracked surface or by continuously submerging concrete in water. It is observed that cracks of nearly 1 mm width can heal completely in favorable conditions as stated above. Long term effectiveness of crazing is yet to be assessed. However, the crazing of the concrete surfaces is not pleasing to the eye and should be prevented as far as possible.

Causes of Crazing

Crazing is due to tensile stresses caused by shrinkage on the top exposed surface relative to the mass of concrete. This shrinkage can occur due to the following:

- Differential thermal movements.

- Differential moisture movements.

- Carbonation shrinkage of the surface. the brittle layer formed from the products of carbonation on the surface, crazes due to shrinkage.

- Alkali-Silica reaction also leads to the crazing of concrete surface.

Preventive Measures

The measures which can be adopted at site to reduce crazing are given below:

- Avoid rich concrete mixes with high cement contents.

- Adopt the lowest possible cement and/or water content, consistent with workability, strength, and durability. The use of admixtures like plasticizers or superplasticizers can greatly help in reducing the cement and/or water content of the concrete mix.

- Avoid non-cohesive and under sanded concrete mixes.

- Curing should commence as early as possible to avoid rapid drying of the concrete surface due to high ambient temperatures, low humidity, and high wind conditions. The curing process should be continuous avoiding wetting and drying cycles.

- Trowelling for a smooth finish must be avoided on the top surface of the slab. Excessive trowelling causes crazing on the smooth surface.

- Remove the surface skin either by brooming or by any other method. Rougher surfaces resist crazing better than smooth troweled surfaces.

- Limit the maximum size of aggregate.

- Avoid smooth and non-absorbent formwork. The surfaces being smooth and non-absorbent cause crazing. Smooth steel plates or sealed plywood shutters can cause crazing. Normal plywood formwork is preferred.

Summary

Long Term Drying Crazing

Time of Appearance:

After 1 to 7 days or much either

Types/Locations:

- Smoothly floated concrete of slabs.

- Against formwork in fair-faced concrete.

Primary Causes:

- Over trowelling.

- Impermeable and smooth formwork (steel).

Secondary Causes:

- Poor/inefficient curing

- Rich concrete mixes

Preventive Measures:

- Improve early curing

- Avoid over trowelling and non-absorbent smooth formwork

- Avoid using rich concrete mixes