Batching is the process of measuring materials or ingredients to prepare concrete mix or mortar mix is known as batching of concrete or mortar.

The batching of concrete ingredients or mortar material is the same as preparations of a dish in cookery according to a recipe wherein different ingredients depending on their individual properties have to be mixed in the right proportions to give the necessary flavor and taste. Therefore, the process of batching is as important to concrete as an accurately proportioned and cooked dish is important to our taste buds.

Methods of Batching

There are two methods of batching commonly adopted for cement and aggregates. They are as follows:

- Proper volumetric batching of all ingredients, using measured boxes or farmas and with control of filling them to brim and leveling. Sometimes on the construction site cement is batched by volumetric measure or weighed.

- Proper Weighing is done of all ingredients of concrete or mortar either utilizing a weight batcher or utilizing the weighing system on the batching mixing plant.

Batching of water should be generally carried out by utilizing a measured container or by using water measuring meters or gauges. Random adding of water can cause great harm to concrete by way of strength variations and loss of durability of concrete.

Accuracies needed for measuring different materials of concrete are suggested as follows:

| Materials | Accuracy of measurement % of batch quantity |

| Aggregates | + 2 to 3 |

| Cement | + 1 to 3 |

| Water | + 1 to 3 |

| Admixtures | + 3 to 5 |

It is always preferable to weigh batch cement and aggregates separately. This is important because the weight of cement in a batch is small and critical in comparison to that of the weight of combined fine aggregates and coarse aggregates. There is always some amount of moisture present in the aggregates, particularly in the sand. Hence, if cement & aggregates are batched in the same container some cement particles and particles of wet sand will stick to the sharp corners of the hoppers and eventually set thereby decreasing the capacity of the hopper and also resulting in incorrect weighment.

Volumetric Batching

For volumetric batching, it is convenient to make steel boxes or wooden boxes, or farmas of different sizes or volumes. It is generally preferred to have boxes of various sizes readily available at the site so that any adjustment which is required to be made by way of change in the mix design of concrete or due to bulkage of sand can be done easily.

It is recommended to have the following boxes or farmas at the site:

| Width (cm) | Height (cm) | Depth (cm) | Volume (lits.) | Qty. (Nos.) |

| 33.33 | 30 | 20 | 20 | 1 |

| 33.33 | 30 | 25 | 25 | 2 |

| 33.33 | 30 | 30 | 30 | 2 |

| 33.33 | 30 | 35 | 35 | 2 |

| 33.33 | 30 | 40 | 40 | 2 |

| 33.33 | 30 | 45 | 45 | 2 |

| 33.33 | 30 | 50 | 50 | 1 |

The volumetric batching of aggregates can be fairly accurate if the site has mobilized the above sizes of boxes. However, the following precautions are very essential:

- Boxes or farmas should not be heaped but leveled to the brim.

- Bulkage correction of sand should be done if moist natural sand is batched.

- Water quantity to the extent of surface moisture present on the aggregate should be reduced.

- 12 Nos. of boxes should be available at site per mixer.

- The boxes used should be of good quality preferably made of steel plates, of 2.5 mm thickness or 12 gauge, and having rigid pipe handles of adequate length.

Weigh Batching

Weigh batching of aggregate is generally preferred. However, the locally available weight batchers don’t function properly because of the poor metallurgy of their components like levers, knife edges, and springs. Besides, maintenance and regular calibration are most often neglected at the site.

Generally, the head load of material is dumped into the weighing pans by the workers. This dumping causes an impact at regular intervals on the weighing mechanism and harms the mechanism.

Care is also required to be taken to ensure that the workers dump one type of aggregate in the weighing pan at a time. It is often observed that because of poor control at the construction site head loads of various types of aggregates are put simultaneously resulting in chaotic batching. It’s also important to control the loading of the aggregates so that the exact weight of a particular size of aggregate is added till the pointer shows the correct indication. The workers/labors generally dump full head loads without reading the indicator scale as a result of which correct weight isn’t generally batched causing variations.

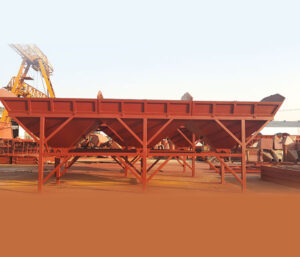

Weigh batching is also done in modern concrete batching and mixing plants which have very sophisticated automatic microprocessor-controlled batching arrangements. Not only the aggregates are batched in correct proportion but also their moisture content is automatically determined and an essential corrective action is taken so that mix has correct consistency as desired.

The system operates to accuracy or correctness of as much as 0.2% relative moisture & it enables every desired consistency range to be maintained and further checks on consistency (slump) are superfluous. Hence, without doubt, these types of equipment, which is now in use at few sites in our country, have the best possible controls to give excellent quality and speed of batching of all ingredients of concrete.