Ordinary Portland Cement is a very finely ground chemical. It is hygroscopic in nature and therefore it can easily absorb moisture from the air. Cement should therefore be protected from dampness and high humidity as it can rapidly lose its strength and get transformed into lumps rendering it unsuitable for use.

During the monsoon, every year there is considerable damage to cement due to incorrect storage and transportation. It is therefore important to have a proper storage arrangement at the consumer’s end.

Storage Shed

The building where the cement bags are to be stored must be a totally watertight structure.

- The sidewall of the shed should have a minimum 9’’ brick masonry plastered on both faces.

- The roof of cement shed/godown can be either of a leak-proof reinforced concrete slab or of adequately sloped water tight galvanized/asbestos sheets.

- The small windows are provided at the sill level and normally kept tightly shut. Due to this, the moisture or rainwater is prevented from entering into the shed.

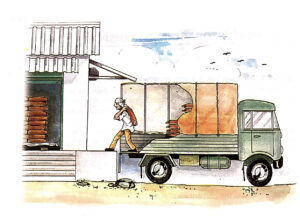

- The height of the plinth of the cement godown should be built in such a way that the bottom level of the truck is of the same height as that of the godown so that, the loading/unloading operations of the bags are done conveniently.

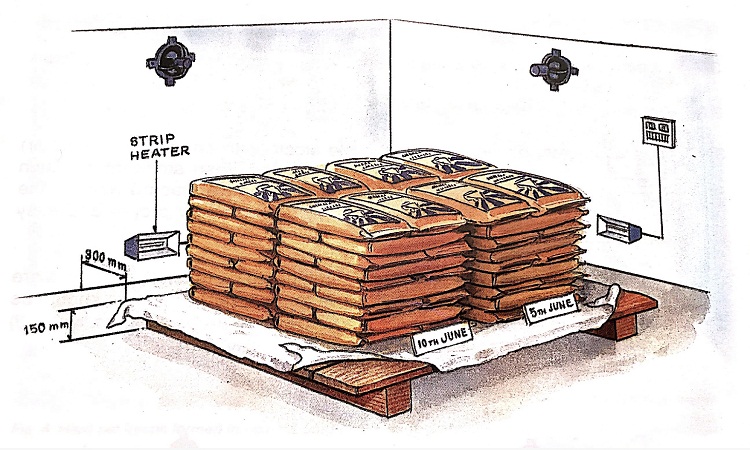

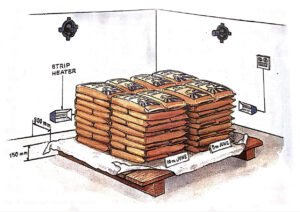

- The floor of the shed should be of a minimum 150 mm thick densely compacted concrete slab on rubble soling. It should be in the proper line, level, and slope. All necessary precautions must be taken to keep the floor completely dry.

Precautions While Storing/Transporting Cement Bags

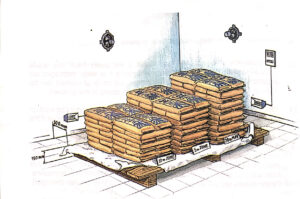

- Bags should not be stacked more than 8 bags high if the adequate storage area is available. If the storage area is not adequate than higher stacking, but not more than 15 bags high, can be permitted.

- If the stack is more than 8 bags should be arranged in layers with an alternate layer of bags arranged in header and stretcher fashion to give the stack better stability.

- All bags must be stored at least 0.3 m away from the walls. For better and easy handling 1 m wide passages are required to be kept in such a manner that old stock of cement can be removed without disturbing the fresher stocks stored in the godown.

- Wooden planks or sleepers covered with plastic sheets should be kept on the floor and then the cement bags stored on top of it. This is a must if the godown has a low plinth.

- If wooden sleepers/planks are not provided two layers of plastic sheets must be spread on the entire floor area in a crosswise manner and repeatedly checked if it needs replacement. It is also recommended to cover the cement bags with 700 gauge plastic sheets especially in humid areas or in monsoons. Plastic sheets should be handled with care so that they are not damaged.

- To reduce the air circulation the stacks of cement bags must be stored as close as possible.

- Install the strip on walls at suitable locations if humidity is very high.

- Install exhaust fans on blank walls to improve ventilation.

- It is absolutely necessary that the old stock (with earlier week number) should be removed for consumption first and fresh stock later. Each consignment should be stacked separately and a placard bearing the date of arrival, week number should be displayed for proper and easy identification.

- When the bags are to be removed, care should be taken that all bags are not removed from the top layer. It is recommended that bags should be removed from two or three layers in a stepwise manner so that the pile is stable and will not topple easily.

- Owing to the pressure on the lower layers of bags the cement lumps together within the bag. If there is moisture ingress from the floor and if the bags in lower layers are not properly protected as suggested in points hard set cement lumps will be formed in the bags. If there is no moisture ingress caking of cement particles will develop within the bags and will cause what is called a “Warehouse pack”. This can be easily removed by rolling the bag just before removing it from the storage shed.

- Trucks should not be allowed to enter the storage sheds if the plinth of the shade is at the road level. Dirt and moisture or even water will create problems of cement contamination and damage.

- Loading and unloading of cement bags onto the trucks should be done under proper cover during the monsoons.

- Cement should not be loaded onto the trucks directly. The plastic sheet must be spread on the truck’s floor and then cement bags unloaded over it. Due to huge gaps between the wooden planks on the truck’s floor water often gets splashed onto the lower layers of bags thereby damaging the cement in it.

- Tarpaulin sheets are not waterproof. Water can seep through them if it collects on the top. It is therefore recommended that cement bags after being loaded onto the trucks should be properly covered with plastic sheets and if required second layer tarpaulin cover over the plastic sheet can be given for more rigidity.

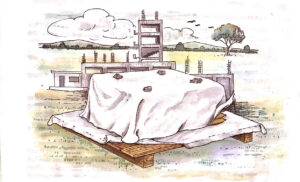

- Trucks without proper plastic sheets/tarpaulins should not be permitted to carry cement. This is extremely important during the monsoons. Many times cement bags have to be stored at the worksites in the open. In such cases, minimum bags should be taken out for each day’s work and the balance bags, which are not consumed, should be returned back to the proper storage shed at the end of the day.

- The open stockpile should be well covered with polyethylene sheets and sheets be properly weighed down. This protects cement against moisture ingress from the atmosphere. An additional layer of tarpaulin over the plastic sheet can give better protection to cement and reduce the chances of damage to the plastic sheet.

- Open storage must be avoided during monsoon in any case.