There are simple field tests of aggregates that are required to be carried out in the field to enable the site supervisor to determine the quality and the proportions required to be taken in the concrete mixes.

Before the tests are performed, it is very important to collect a proper representative sample of the aggregate to avoid wrong results.

The minimum quantities needed to be sent to a testing laboratory are generally as follows:

| Fine aggregates (sand) | 13kg |

| Coarse aggregates or all in aggregates maximum size 20mm | 25kg |

| Maximum size 40mm | 60kg |

However, this quantity is not sufficient for taking trial mixes. More materials are generally required for concrete mix trials.

Sampling

The samples of aggregates need to be obtained using the following steps:

- The heap must then be flattened and divided into four equal quarters on a clean, flat, and hard surface.

- Throw away the opposite quarters and mix the other two quarters.

- Once again divide the mixed aggregates from two selected quarters and further continue quartering till the quantity needed for various tests is obtained.

If a riffle box is available, then quartering is unnecessary as it has several compartments and chutes that split the samples uniformly as required.

Surface Moisture Content of Aggregates

It is very important to know the surface moisture of all aggregates so that total water in the mix can be controlled and kept reasonably constant. The moisture content of natural sand can vary from load to load. However, crushed sand & coarse aggregates may not have surface moisture except during the monsoon. Generally, they are received at a construction site in a dry form.

It is very essential to determine surface moisture on the aggregates so that water added to the concrete mix is reduced proportionately. It is also necessary to determine the absorption capability of the aggregates as the water in the concrete or mortar mix will get absorbed into the aggregates and show a rapid drop in the workability (slump). Thereby creating difficulties while placing and compacting. It is, therefore, essential to proportionately increase the water added to the concrete mix. It must be noted that only the surface moisture influences the water to cement ratio, strength, and durability of the mix.

A simple method to determine the surface moisture of moist or wet aggregates is as follows:

Frying Pan Method

The following apparatus is required: A frying pan or metal tray, gas stove or an electric hair dryer, a metal or glass stirring rod, and scales to measure.

For coarse aggregate 2kg sample is adequate and for fine aggregate 0.5kg sample is adequate.

The wet/moist sample is then weighed accurately. The wet weight (W) is noted. The aggregate is then very gently heated on the metal plate or frying pan & stirred with a metallic rod to maintain equal distribution of heat. The coarse aggregates become surface dry when the sheen disappears from the surface. The fine aggregates become surface dry when it just begins showing free-flowing properties.

The aggregate is then cooled and reweighed. The surface dry aggregate weight (Wsd) is noted. The surface moisture is then calculated as follows:

Surface moisture = (W-Wsd/Wsd) x 100%

Overheating must be avoided as it won’t give the correct surface moisture.

If heating is continued either on the frying pan or in the oven till the aggregate is bone dry water absorption capacity of the aggregate can be determined. The bone dry aggregate weight is then noted (Wbd) after continuous heating. The absorbed water content is then calculated as follows:

Absorption = (W-Wbd/Wbd) x 100%

Likewise, if the dry aggregates are received on-site and absorption capacity is to be determined then the aggregates are first soaked in water and then the above methods are deployed to determine the absorption capacity of the aggregates.

Automatic Measuring of Surface Moisture Content

In modern batching plant measuring of surface moisture in aggregates and adjustment of water to be added to the concrete mix are fully automatic and such recording and the corrective system have a tolerance of less than ± 0.6%. A rod neutron probe, double-rod resistance probe, or a microprocessor-controlled MFM 85 litronic moisture recorder is achieved in ready mix concrete plants.

Some systems operate to an accuracy of as much as 0.20% and also simultaneously keep to consistency or slump of the concrete mix under control.

Silt Test for Sand

The permissible silt content in the sand (fine aggregate) is specified in the Bureau of Indian Standards by weight. However, silt content determination by volume is generally much simple and at the same time gives a fairly good indication of the proportion of silt in the fine aggregates. Although, this method can only be utilized for natural sand; it should not be used for crushed rock sand. The apparatus required for this test is only a 250ml glass measuring cylinder.

The silt content determination for fine aggregate by volume is done in the following manner:

- The glass cylinder is filled with a saltwater solution (concentration of the solution will be teaspoon full of common salt for every 570ml) up to 50ml mark.

- Add sand (fine aggregate) until the level of the sand is up to the 100ml mark.

- Add further saltwater solution till the 150ml mark is reached.

- Place the palm on the mouth of the glass cylinder & shake it vigorously.

- Place the cylinder on a hard leveled surface and tap it all around so that sand is leveled.

- Wait for 3hrs for silt to settle on top of the sand.

- Measure the thickness of the silt layer & the height of the sand. The silt content can be calculated as follows:

Absorption = (Thickness of silt layer/Height of sand + silt) x 100%

The silt content should not exceed 8% after 3 hours. If the silt content exceeds the limit, then silt percentage by weight be determined in the laboratory. If silt content by weight exceeds 3% then sand washing is necessary.

After a few tests are done a co-relation can be developed for silt layer thickness at various intervals of time.

The silt content at 10min can be fixed as an inspection criterion. At one of the sites, this percentage happened to be 20%. If the silt content was found to be less than 20% within 10min, the trucks were allowed to be unloaded.

No truck should be allowed to be unloaded till silt content is checked.

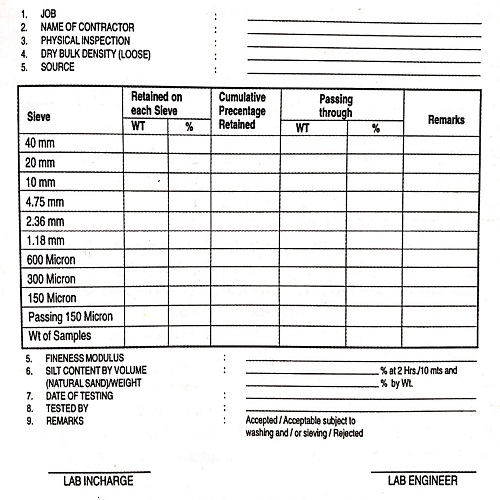

Sieve Analysis

The proportion of various sizes of particles constituting coarse and fine aggregates are determined by sieving. Fine aggregates must be dried before sieving. The dried sample will give a more accurate analysis.

Coarse aggregates are sieved through the following sieve sizes: 40mm, 20mm, 10mm, and 4.75mm.

Fine aggregates are sieved through the following sieve sizes: 10mm, 4.75mm, 2.36mm, 1.18mm, 600 microns, 300 microns, and 150 microns.

This test is done initially for mix design of concrete and later conducted periodically for mix proportion adjustments if it is suspected that the grading of aggregates has changed considerably. The size of samples taken for sieving is dependent on the maximum aggregate size as suggested below:

| Maximum aggregate size (mm) | Minimum weight of sample (kg) |

| 40 | 15 |

| 20 | 2 |

| 10 | 1 |

| 4.75 | 0.5 |

Each sieve is shaken separately for a period not less than 2mins or until no more traces of material passes. Care should be taken to see that sieve nets are not ruptured or damaged. Sieves should have square-shaped openings. Care should also be taken to clean the sieves so that particles do not block the sieve net.

Precaution is necessary that sieves do not get overload and materials should not overflow while sieving.

The fineness modulus is the cumulative percentage retained on each of the sieves stated above divided by 100. Sand (fine aggregate) can be classified according to its fineness modulus (FM).

| Types of sand | F.M. |

| Very fine | Below 2.2 |

| Fine | Between 2.2 to 2.6 |

| Medium | Between 2.6 to 2.9 |

| Coarse | Between 2.9 to 3.2 |

| Very coarse | Above 3.2 |

The field test results of aggregate can be presented in form of a worksheet as given below. The fineness modulus of sand can be calculated to give the site engineer an idea of the overall fineness or coarseness of aggregates received at the site.

Only sand with between FM 2.6 to 2.9 was considered suitable for nominal mix proportion. However, at various sites, independent of FM, the sand is utilized in nominal mix proportion without adjustment of FM by adding fine sand or removing excess fine or coarse particles in any. Another alternative adjustment will be to increase the quantity of sand and decrease the coarse aggregates if sand has FM greater than 2.9 or decreasing the quantity of sand and increasing the coarse aggregates if sand has FM less than 2.

In some regions of our country, natural sand has coarser particles and a considerable percentage of it is observed to be retained on a 4.75mm sieve. Any material which is retained on a 4.75mm sieve cannot be considered sand. It should be considered as coarse aggregate. If this is not done the concrete mix will be understood as causing poor finish, segregation, and honeycombing. This reduces the concrete strength and durability considerably.

Bulkage of Sand

When sand is damp the water coating the surface of each sand particle causes separation of particles from one another due to surface tension. This causes the sand to bulk. Bulked sand occupies more volume and hence if volumetric measuring is done while proportioning it, bulkage correction is necessary.

The bulkage test is done as follows:

- The sand is filled, in the loose condition in a box or container of measured height (H cm).

- The box is then overflowed with water & rodding is done to make the sand settle and consolidate. Care should be taken that sand doesn’t overflow during the flooding and compaction.

- The sand is then leveled in the box or container & the drop in height is measured (h cm).

- Bulkage is calculated as follows:

Bulkage % = (h/H) x 100%

Dry sand possesses the same volume as fully saturated sand. The bulkage will vary from load to load and day to day depending on the fineness of sand and its surface moisture content. It is, therefore, very essential to make bulkage corrections by checking the actual bulkage of sand proposed to be used by volumetric batching for mortar or concrete.

Heaping boxes at random is not a correct method to make allowance for bulkage. It is necessary to correctly measure the bulkage of sand and make adjustments by using the right size boxes depending on the bulkage observed.

Conclusion

Aggregates differ in quality, type, and grading from place to place. However, the engineer at the site has to first make use of the aggregates available in the vicinity of the site for economic reasons. If the aggregates available near the site are not suitable, it is only then the engineer has to survey the areas further away to get the most economically and technically suitable aggregates.

It is observed that in particular areas; there is an unnecessary reluctance to change from natural sand to crushed sand or vice-versa and from crushed coarse aggregates to gravel aggregates or vice-versa. It is best for the engineer to take trails of concrete mixes prior to full-scale use if such changes are necessary. However, if the trials are successful there is absolutely no harm to change.

A large number of projects have been executed either with crushed coarse aggregates or with gravel. Similarly, it is true for natural as well as crushed sand. The engineer has to understand that if the parent materials i.e. Basalt or granite are the same then there is absolutely no harm in using it either in a natural or crushed form so long as it is free from deleterious materials.