Chemical admixtures are the ingredients in concrete other than Portland cement, water, fine aggregates, and coarse aggregates that are added to the mix immediately before or during mixing concrete.

Producers utilize chemical admixtures to reduce the cost of concrete construction; to modify the properties of hardened concrete; to ensure the concrete quality during mixing, transporting, placing, and curing; and to control certain emerging during concrete operations.

Successful use of chemical admixtures depends on the use of appropriate methods of batching & concreting. Most admixtures are supplied in ready-to-use form and are added to the concrete at the job site.

The effectiveness of chemical admixture depends on different factors including; type of cement, cement content, water content, mixing time, slump, and temperature of the concrete and air.

Sometimes, effects similar to those achieved through the addition of chemical admixtures can be achieved by altering the concrete mixture-reducing the water-cement ratio, adding additional cement in concrete, using a different type of cement, or changing the aggregate & gradation of aggregate.

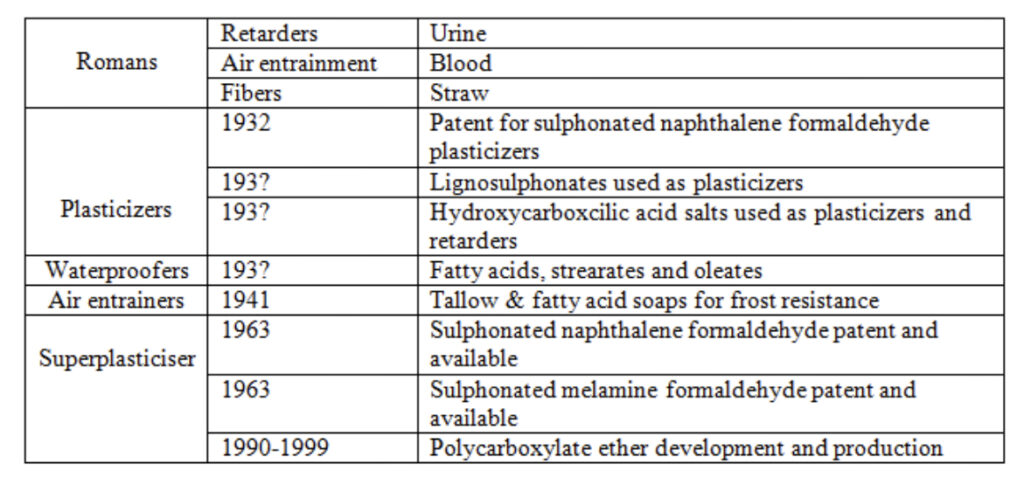

History of Chemical Admixtures

Types of Chemical Admixtures

- Accelerators

- Retarders

- Plasticizers

- Superplasticiser

- Air-entraining admixtures

- Water reducing admixtures

- Mid-range water-reducing admixtures

- High-range water-reducing admixtures

- Plasticizers for flowing concrete

- Hydration-control admixtures

- Corrosion inhibitors

- Shrinkage reducing admixtures

- ASR (Alkali-aggregate reactivity inhibitors)

- Coloring admixtures (Pigments)

- Damp proofing admixtures

- Permeability-reducing admixtures

- Pumping aids

- Bonding admixture and Bonding agent

- Grouting admixtures

- Gas-forming admixtures

- Air detainers

- Fungicidal, Germicidal, and Insecticidal admixtures

- Antiwashought admixtures

Function of Chemical Admixtures

- To accelerate the initial set of concrete.

- To dim the entail set.

- To enhance workability.

- To improve the flowability and permeability of concrete.

- To reduce the separation in grout & concrete mixtures.

- Increasing the strength of concrete by decreasing the water content & increasing the density of concrete.

- To increase the durability of concrete.

- To reduce the capillary flow of water through concrete & increase its imperviousness.

- To control alkali-aggregate expansion or alkali-silica reactivity.

- Prevents corrosion of reinforcement in concrete.

- Increase resistance to the chemical attack.

- To reduce the heat of hydration.

- To increase the bond between old & new concrete surfaces.

- To improve the bond of concrete to the steel reinforcement.

- To decrease the weight of concrete per cubic meter (m3).

Effect of Chemical Admixtures on Properties of Fresh Concrete

Workability

The main reason why admixtures are used in concrete is to improve the workability of concrete. Improved workability helps in the compaction of concrete and thereby removal of entrapped air from the concrete mass. Entrapped air within the loss of the concrete causes strength and durability.

The slump of the concrete mix can be greatly increased if a chemical admixture (plasticizer) is used.

Cohesiveness

It is essential to design a concrete mix that has proper cohesiveness. Cohesive (sticky) mixes keep the coarse aggregate and fine materials in the concrete mix together. This helps in reducing the chances of segregation and thereby reduces the chances of large porosity in the concrete. Cohesive concrete mixes can also reduce the bleeding of concrete and this, in turn, helps in the reduction of plastic shrinkage cracks and improvement in the strength and durability of the concrete top surface.

Retardation / Retention of Slump

Retardation of concrete is generally measured by the time taken for concrete to reach a particular value of penetration resistance. If an admixture is used to achieve retardation then the improvement in retardation is measured as a difference between the stiffening rate of a reference (without admixture) mix and the mix containing the admixture.

Retardation of the concrete mix using a suitable admixture could be very useful when large concrete pours are carried out in high ambient temperatures. High temperatures hasten the setting time of concrete resulting in difficulty in compaction thereby causing cold joints between the subsequent layers of concrete. It can result in porosity and problems related to loss of strength and durability.

Retardation of the concrete mix using an admixture prevents the formation of cold joints as the lower layer of the concrete will not stiffen till such time as the subsequent layer is placed and compacted over it. Plasticizers having retardation characteristics, if used in a concrete mix, can help in extension of the setting time of concrete and thereby help in placing and compacting concrete in a massive pour in warm/hot weather conditions.

Loss of workability of the concrete takes place due to several reasons. This drop-in workability takes place from the time the concrete from the mixer is unloaded to the time it is transported, placed, and compacted in the formwork. A drop in the workability beyond a certain point will create difficulties in placing and compacting concrete. This is in turn can be harmful to the strength and durability of the concrete. It should be clearly understood that retardation of the concrete’s setting time and retention of concrete’s workability are two separate aspects.

Workability retention, unlike retardation, is not easily defined. Retardation slows down cement hydration which in one way also helps in retention of workability as less water is consumed due to cement hydration during the initial stages and therefore more water is available for workability.

However, retardation has little effect on the workability loss. Workability of concrete with retarding chemical admixture will drop at the same rate as reference or control mix until a slump of 50mm to 75mm is reached. It is only around this level and below that retardation affects workability loss.

The best way to get the required workability at the time of placing and compacting is by starting at higher workability. In order to achieve this, there are different ways. Additional water if added will improve the workability but the strength and durability of the mix will be seriously affected. It is therefore very important that workability improvement shouldn’t be done at the sacrifice of the strength and durability requirements of concrete. This can be achieved by using admixtures which improves the workability significantly without a change in the water-cement ratio or cement content.

If the concrete mix is designed for higher workability it will take a long time before the workability falls below the required target value for placing and compacting the concrete.

Specially formulated retarders cum plasticizers are available with an optimal combination of both requirements of workability retentions as well as retardation.

Effect of Chemical Admixtures on Properties of Hardened Concrete

Reduction of Permeability of Concrete and Improvement in Durability of Concrete

It is also observed that W/C reduces if a plasticizer is added to a concrete mix without a change in the workability of the mix. It is a well-known fact that. The lower the W/C, the lesser is the permeability of concrete. This results in less ingress of moisture, chlorides, and other aggressive chemicals as the capillary pores are smaller and get blocked faster when the W/C is low.

Besides, due to the reduction in W/C, the strength is increased. Concrete with higher strength is more resistant to carbonation.

The use of plasticizers also improves the freezing and thawing resistance of concrete.

Reduction of Heat of Hydration

The chemical reaction between cement and water creates heat and increases the temperature of concrete. This temperature depends on the quantity and properties of the cement in the concrete mix and the degree of cooling done at the time of concrete production. At the center of large blocks of concrete such as foundations, rafts, etc. the temperature rise can be around 130C for every 100 kg of cement per cubic meter of concrete. A large temperature rise caused due to the use of rich mixes in large pours causes a temperature differential between the interior and the exposed surface of the concrete. This causes thermal stress due to the temperature difference between the concrete’s interior and the concrete surface. This can lead to severe thermal cracking.

A reduction of cement content results in a reduction of the heat of hydration and thereby problems associated with it are reduced. If a plasticizer is used in concrete, the cement consumption can be reduced without a change in W/C or reduction in strength.

Shrinkage and Creep

Drying shrinkage cracks are generally caused due to loss of water from the capillary pores smaller than 0.5 micron, loss of absorbed water from close to a solid surface, or loss of water present between the layers of calcium-silicate hydrate (C-S-H) structure.

The loss of water causes strain and the resultant stress due to volume reduction. If this stress is greater than the concrete strength, then drying shrinkage cracks are caused.

Higher cement content and water content in a concrete mix can cause more drying shrinkage cracks. Concrete capillary pore purification due to the use of chemical admixture can also cause more drying shrinkage cracking problems.

In general, these properties of plasticized concrete aren’t significantly influenced as compared to identical concrete made without their use. To a certain extent, plasticizers help in the reduction of cement or water and therefore the reduction of hydrated paste and hence reduction of problems related to shrinkage and creep. This advantage is, to a certain extent, countered by the above fact that plasticizers also help in the refinement of the pore structure of the hydrated cement paste.

However, there have been no studies to establish any serious adverse effects on concrete shrinkage and creep if the dosage of the plasticizer used is within its allowable limits.

Advantages of Chemical Admixtures

- Increase workability of concrete without increasing water content or decrease the water content at the same workability.

- Retard or accelerate the time of the initial setting.

- Prevent or reduce shrinkage or create slight expansion.

- Modify the rate or capacity for bleeding.

- Reduce segregation.

- Improve pumpability.

- Admixtures provide initial strength in concrete.

- It reduces the initial heat of hydration and overcomes the problem of thermal cracking in concrete; if there is excess heat of hydration the cracks can spread to the fresh concrete.

- There are mixtures of concrete that reduce the initial strength of concrete but increase the strength of hardened concrete compared to normal concrete.

Disadvantages of Chemical Admixtures

- This increased drying shrinkage.

- This provides less resistance to sulfate attack.

- CaCl2 high risk of corrosion of steel so, not allowed in reinforced concrete.

- It is more expensive and less effective.

The Adverse Effects of Excess Use of Chemical Admixtures in Concrete

- One of the common plasticizers generally used is lignosulphonate acid in form of calcium or sodium salt.

- A higher dosage of super-plasticizer affects the shrinkage & creep properties of concrete.

- A higher dosage of plasticizer may cause segregation of concrete and premature stiffening under certain conditions.

- A higher dosage of super-plasticizer may increase the rate of loss of workability of concrete.

- Excessive use of accelerators causes more heat evolution and there are chances of cracks in the concrete.

- In the case of air-entrained concrete strength decreases in properties to the amount of air. It is observed that 1% of entrained air reduces strength by about 5.5%. the optimum air content is ranging from 3% to 6%.