Bridge structures deteriorate due to various reasons over time. In many situations, merely repairing the cracks and spalls are not sufficient and there is a need to strengthen the structure in order that it desired purpose. There are various conventional practices for strengthening which have extensively used but they have many shortcomings. Off late a new technique for strengthening the concrete structure with the help of fiber wrapping has come up.

In this article causes for the strengthening of bridge structures, existing practices along with its merit and demerits, and strengthening with the help of carbon fiber reinforced polymer has been discussed.

Introduction

Concrete is one of the most versatile, construction materials, and the majority of the bridges build across the world are concrete structures. Concrete over a period of time deteriorates for various reasons and requires maintenance, rehabilitation/strengthening work in order to continue its serviceability.

There are various strengthening/rehabilitation procedures. Strengthening with the help of carbon fiber reinforced polymer (CFRP) is one of them. This is a new technique having tremendous potential.

Let’s understand, why strengthening and strengthening procedures with the help of carbon fiber reinforced polymer (CFRP) have been discussed.

Requirement of Strengthening of Concrete Bridges

Strengthening of a concrete bridge structure may be required on account of one or a combination of the following:

- Deterioration of structure due to environmental effect.

- Revision in loading standard.

Deterioration of Structure Due to Environmental Effect

Concrete is heterogeneous as well as porous material. It allows the ingress of air and moisture in it. Ingress of moisture, air allows chemicals like carbon dioxide, chlorides, and sulfates to enter into the concrete. They deteriorate concrete causing the concrete to crack. These cracks accelerate further deteriorate and may cause the structure to lose its structural integrity and strength.

Revision in Loading

The loading conditions may change over time due to changes in traffic conditions, axle loading, or due to changes in the loads considered in the relevant codes. The bridges built earlier are now being subjected to higher loads due to an increase in axle loads. This increase in loads leads to strength deficiency in the structure and it needs to be furthered strengthened in order to cater to its serviceability.

Traditional Strengthening Procedures

Traditionally the strengthening of structures has been done by one or more of the following methods:

- Increasing the section of the member by jacketing

- Providing steel plates on the face of the member

- External prestressing

The above methods have been successfully implemented in many projections across the globe. But there are certain demerits to the above methods:

- Strengthening for the vertical portion of the structure is possible like columns, piers, etc. But, the horizontal portion of the structure like girders and deck slab, the same is either not possible or very difficult

- Weight of the structure increases. So the structure needs to be analyzed for the increase in dead load as well as the effect in seismic condition.

- In case of large span girders, it becomes difficult to handle the steel plate due to its heavyweight

- In case of plate joining is required due to longer span, the difficulty is being faced in providing butt-welded joint

- Corrosion of externally provided steel plate is a major concern

- Corrosion of prestressing strands.

Carbon Fiber Reinforced Polymer

Many raw materials and techniques are being developed for the strengthening of structures. Carbon fiber is one of the materials which is used in combination with other materials from a composite. The properties of carbon fibers such as high stiffness, high tensile strength, low weight, high chemical resistance expansion make them one of the most versatile material for strengthening.

Each carbon fiber thread is a bundle of many thousand carbon filaments. Single such filament is a thin tube 5-8 micrometers and consists of pure carbon. Construction composites that are most commonly reinforced with carbon fibers are called as carbon fiber reinforced polymer. To make a carbon fiber sheet, carbon fiber fabric is saturated with epoxy resins and heated at high temperatures. The polymer used in carbon fiber reinforced polymer is most often epoxy, but other polymers, such as polyester, vinyl ester, or nylon are sometimes used. Commercially, carbon fiber reinforced polymer is available as fabric as well as sheet or plates.

Properties of carbon fiber reinforced polymer (CFRP) depend upon the layouts of carbon fibers and the proportion of carbon fibers relative to the polymer. Carbon fiber reinforced polymer materials re distinguished by their extremely high strength, rigidity, durability, and high resistance to corrosion, low density, excellent damping properties, and high resistance to impacts. The main disadvantage of carbon fibers is their catastrophic mode of failure since the carbon fibers are brittle in nature.

Applications for Carbon fiber reinforced polymer

The application fields of carbon fiber reinforced polymer include bridges, buildings, tunnels, chimneys, box culverts, etc. The bridge piers, girders, deck slabs, and building beams, columns, and slabs are the most common to be strengthened. Bridge and chimney have witnessed great success owing to the use of carbon fiber-reinforced polymer. Typically concrete bridge deck has a life of 30-40 years depending upon the durability enhancing measures taken during construction. Old concrete decks constructed with unprotected steel are deteriorating rapidly. Wrapping around bridge sections can restore the load-carrying capacity if the member to its original condition. It can also help in enhancing the ductility of the section, greatly increasing the resistance to collapse under earthquake loading. The fiber wrap systems are also being used to repair deteriorated concrete piers, concrete arch, pier caps, and damaged beams.

Column, beam, and slab strengthening is another very important application of carbon fiber composites. In flexural reinforced concrete members, the addition of carbon fiber improves the modulus of rupture (bending strength).

Methods for Strengthening Various Structural Elements of a Bridge

Depending upon case-to-case and member-to-member, the strengthening method differs. The most common methods are described below:

Strengthening Scheme to Enhance the Flexural and Shear Capacity of Girders and Deck Slab

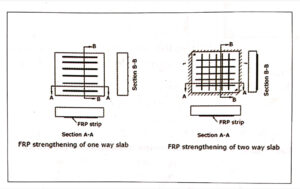

Carbon fiber reinforced polymer (CFRP) plates are paste to the bottom (generally the tension face) of the girder or the deck slab. In the case of a cantilever section, the plates have to paste on the top. This increases the strength of the beam, deflection capacity, and stiffness (load required to make unit deflection).

While strengthening the member, the orientation of the fiber is of utmost importance. This is so because the strength of carbon fiber reinforced polymer (CFRP) product is not equal in all directions. In the axial direction of the fiber, its strength is maximum. In flexural members, tension is along the span direction & mainly for that, steel reinforcement is provided. In a similar way, while providing the carbon fiber reinforced polymer (CFRP) sheet, the same should be in such a manner that the direction of the fiber should be mainly along the span.

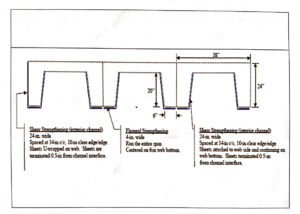

A typical arrangement for the strengthening of a bridge girder system for flexural and shear is as shown in the figure.

If the member needs strengthening of shear, then carbon fiber reinforced polymer (CFRP) strips and sheets can be paste in “U” shape around the sides and bottom of the beam.

The typical arrangement for strengthening of deck slabs as shown in the figure. There may be certain possibilities that in some locations, slabs are bearing concentrated load and the maximum moment is localized there. In such cases, the provision of carbon fiber reinforced polymer (CFRP) strip should be in the desired zone and not required to be symmetrical in the center.

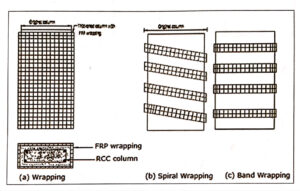

Strengthening Scheme for Enhancing Axial Capacity of Piers

Sometimes, columns, piers, and abutments require strengthening to enhance its capacity. Capacity enhancement might be there either on account of flexural or axial or both. In such a case, whether it is axial, flexural, or combined, the FRP sheet needs to be wrapped all around the piers. A schematic diagram of such strengthening is given in the figure.

Procedure for Installation of Carbon fiber reinforced polymer (CFRP) Surface Preparation

Before the start of the work, it is very much essential to ensure that surface should be clean, dry, free from oil and grease, and any type of loose material.

To ensure little roughness, grinding or light sandblasting can be done followed by proper cleaning of the surface to remove dust particles. Any protrusion should be made perfect otherwise, it may create a void in the nearby area. Crack more than 0.3mm width, if any, needs to be properly epoxy grouted to ensure good quality.

Wet Lay-up Method

After completion of the surface preparation, one coat of epoxy is applied on the surface. Then, the saturated fiber in the appropriate resin is applied on the surface.

Misalignment of the fiber may lead to unsound work, As such, fiber should be properly aligned and slightly stretched to avoid any bend/twist, if any. The number of layers will depend upon the requirement of thickness. After placement of saturated fiber, the same should be properly rolled to ensure its proper compression as well as adhesion to the surface on which the same is applied. The presence of any void will affect the strength.

Utmost care must be taken that the surface should not be wet during the application of carbon fiber reinforced polymer (CFRP) sheets. This can eventually cause the debonding of the sheet and will lead to the loss of load-carrying capacity.

Surface Finish

After completion of the fixing of the carbon fiber reinforced polymer (CFRP) on the member, a coat of epoxy is applied and fine sand is sprinkled on the epoxy to create a rough surface. This surface can now take any further treatment that is required such as cement plaster, paint, etc.

Design Procedures and Codal Provisions

As the technology is relatively new, most of the works have been carried out based on guidelines and published literature only.

Two major references used as guidelines for design practices are:

- State of the Art on fiber-reinforced polymer Reinforcement for Concrete Structure, ACI 440 R- 96.

- Concrete Society 2000 – Design guidance for strengthening concrete structure using fiber composite materials. Technical Report No. 55. The Concrete Society, Century House, Telford Avenue, Crowthorne, Berkshire, United Kingdom.

Conclusion

Though carbon fiber reinforced polymer (CFRP) is a relatively new technology, the scope for application in the construction industry is tremendous. The older bridge structures are requiring strengthening measures either due to deterioration and change in loading.

One of the major restrictions in the implementation of this technology is the high cost involved. As the technology is relatively new, most of the works have been carried out based on guidelines and published literature only. At this juncture there is a need for Government – Industry – Institute partnership to exploit the full potential of Carbon fiber reinforced polymer (CFRP) so that the technology can be used extensively to breathe new life in the aging bridges in India.